Governance

Basic Approach

We understand that our Group’s activities affect many others,

given that we and our major overseas production facilities

have direct business relationships with approximately 800

companies, including suppliers of materials and parts, as well

as companies that provide services, advertising, and logistics,

and even more Tier 2 and other suppliers. We also recognize

that through collaboration throughout the supply chain and

local procurement, we can achieve carbon neutrality, improve

quality, and contribute to local community development.

Based on this understanding, we believe that for all

processes, from the procurement of raw materials to the

manufacture and delivery of parts and products, it is important

not only to comply with laws and regulations but also to

act responsibly, taking into account such factors as the

environment and human rights.

We have formulated “Supplier CSR Guidelines” and “Green

Procurement Guidelines” and work together with all our

business partners to achieve sustainable growth throughout the

supply chain. As compliance with both guidelines is a priority in

our Group’s procurement activities, our procurement division

executives take advantage of opportunities such as supplier

briefings to request that the entire supply chain thoroughly

comply with the guidelines

Supplier CSR Guidelines

The “Supplier CSR Guidelines,” which are based on our Human

Rights Policy, include provisions on respect for human rights,

including the elimination of discrimination and the prohibition

of child labor and forced labor. They require that suppliers

take human rights into consideration, that they undergo CSR

assessments by third-party organizations, and that they clearly

indicate measures taken in response to compliance violations. We

promote collaborative activities with all of our suppliers from the

same point of view. The scope of these activities includes labor

practices, environment management, and compliance.

In addition, to comply with domestic and international laws

and requirements related to environmental and human rights

risks throughout our value chain, we are considering revisions to

our guidelines with input from outside experts.

Green Procurement Guidelines

Our suppliers cooperate with us in various initiatives, such as those indicated below, including meeting the requirements of our “Green Procurement Guidelines.” In addition to Japan, we have introduced the guidelines in overseas production bases, adjusting the guidelines to account for actual conditions in each country and operational details at each location. These production bases are also applying the guidelines to their business partners.

Main Requirements of the “Green Procurement Guidelines”

- Acquire and renew external certifications of environment management systems

- Manage hazardous substances

- Promote the 3Rs (reduce, reuse, and recycle)

- Submit LCA*1 data to allow us to understand the lifecycle environmental impact

- Reduce environmental impact in business activities

- Reduce their environmental impact related to logistics

- LCA stands for Life Cycle Assessment, which is a technique for calculating and evaluating the environmental impact of a product from manufacturing to disposal.

Management Structure

For all material issues, including achieving a sustainable

supply chain, the Group confirms the risks and opportunities

identified from a long-term perspective by those responsible

for each materiality initiative. Our Sustainability Committee

deliberates and decides on initiative targets based on the

external environment and stakeholder needs and expectations

from a medium-term perspective, and uses the PDCA cycle by

checking progress.

We have a structure in which important matters such as reviewing material issues and the overall status of sustainability activities are deliberated and reported at Board of Directors meetings

Strategy

Risks, Opportunities and Impacts

| Risks |

|

|---|---|

| Opportunities |

|

| Impacts |

|

- Business continuity plan

Responsible Resource Procurement

“Conflict minerals” (tin, tantalum, tungsten, and gold) and

cobalt have become a source of funding for armed groups,

resulting in serious violations of human rights.

To ensure that we are not complicit in human rights abuses

through the procurement of these conflict minerals, the Group

promotes responsible procurement by clearly specifying in our

“Supplier CSR Guidelines” the prohibition of child labor, forced

labor, and the nonuse of conflict minerals as raw materials. To

achieve sustainable mineral sourcing, we are considering the

formulation of new policies, including environmental and human

rights due diligence, with input from outside experts. We ensure

the transparency of our raw material procurement along with

our suppliers and live up to our social responsibilities.

Risk Management

Business Continuity Plans in the Supply Chain

A large-scale natural disaster, major outbreak of infectious

disease, or production shortage of specific parts or materials

(such as semiconductors), could interrupt the flow of parts

from our suppliers. We might then run the risk of business

being suspended. To avoid or mitigate such risks, as part of our

business continuity plans (BCPs) in the supply chain, we are

taking measures to identify risks and impacts early on and to

find alternative suppliers and substitute components.

Specifically, we have established a Supply Chain Risk

Management System and ask suppliers to register Tier 2 to Tier

N suppliers, including their factories and overseas suppliers, so

that target suppliers can be rapidly narrowed down. In addition,

we have a system in place that allows us and our business

partners to share information about the status of damage

caused by disasters, the impact of production shortages for

specific parts and materials, and our response to production

plans so that we can take countermeasures.

Confirmation Based on Suppliers’ Commitments to Guidelines

The Company conducts transactions in an appropriate manner,

which includes not violating human rights. We determine

transaction prices and delivery dates following thorough

consultation with individual suppliers.

To ensure that suppliers thoroughly comply with our

“Supplier CSR Guidelines” and “Green Procurement Guidelines,”

we have them submit “Supplier Commitments” and “Declarations

of Conformity to Regulations on Substances of Concern.” We

ensure the effectiveness of our business partnerships by

having new business partners submit these documents before

commencing transactions, and by continuously confirming the

status of the agreement afterwards.

We have expanded these efforts to include our major

overseas bases-Mitsubishi Motors (Thailand) Co., Ltd. (MMTh),

PT Mitsubishi Motors Krama Yudha Indonesia (MMKI), Mitsubishi

Motors Philippines Corp. (MMPC)-and received Supplier

Commitment agreements from suppliers at our major overseas

production bases.

Establishing a Business Partner Helpline

As part of MITSUBISHI MOTORS’ efforts to adhere to the METI guidelines, we have established a Business Partner Helpline for the suppliers of our procurement division. The helpline receives opinions and comments from business partners, quickly identifies compliance issues or concerns, such as legal or regulatory infractions, unfair practices or human rights violations in our procurement activities, and promptly rectifies them, striving to achieve even fairer business transactions.

Metrics and Targets

| Long-Term Targets (2030) |

Promoting CO2 emission reduction activities through collaborations with suppliers/transporters in the fields of procurement and logistics |

|---|---|

| Medium-Term Targets |

|

FY2024 Initiatives

Communicating with Suppliers

Providing suppliers with appropriate information and two-way

communication is essential for supply chain management.

At the end of every fiscal year, we hold a Suppliers Meeting

to explain our procurement policies for the next fiscal year,

attended by approximately 300 companies. Small-scale

meetings between the management teams of suppliers and

our management team are held every year to help foster closer

communication at the management level. These meetings, each

of which involves approximately 20 companies, are conducted

by the MITSUBISHI MOTORS Council, a voluntary organization

of around 180 supplier companies. A total of nine small-scale

meetings were held in FY2024.

Enhancing CSR in the Supply Chain through Third-Party Evaluations

The Company conducts third-party CSR evaluations in the four

areas of the environment, labor and human rights, ethics, and

sustainable procurement, with the aim of raising the level of

CSR activities at our suppliers.

In FY2024, many business partners underwent third-party

evaluations. MITSUBISHI MOTORS plans to continue expanding

the number of business partners who undergo evaluations in

FY2025, and we will focus on improving the scores of those

partners who have already been evaluated (approximately 90%

of all orders based on order value).

Support for Quality Improvements by Suppliers

The Group regularly conducts quality audits and assists with

quality self-checks by suppliers to improve quality along the

entire supply chain.

In FY2024, we conducted process audits for 92 suppliers at

104 plants, and indicated items were generally improved within

three months. Process audits are conducted every one to three

years, with the audit cycle set according to the results of the

previous audit. Quality self-checks are performed by 310 business

partners. Each company is working to improve the weak points

found in the self-check. In addition, we are actively working to

improve communication with suppliers and enhance quality by,

for example, promoting improvements by disseminating the

results of our self-check trend analysis to all suppliers.

We issue monthly Supplier Score Cards, which numerically

represent suppliers’ quality results. This approach has

clarified issues for each company, assisting in the fast and

accurate implementation of improvement measures. In

cases of particularly serious defects, we analyze the causes

and examine the appropriateness of countermeasures in

collaboration with business partners to prevent recurrence.

MITSUBISHI MOTORS cooperates on defect prevention activities

to keep defective parts from being delivered and ensure we

are able to provide customers new models with confidence.

Promotion of Localization

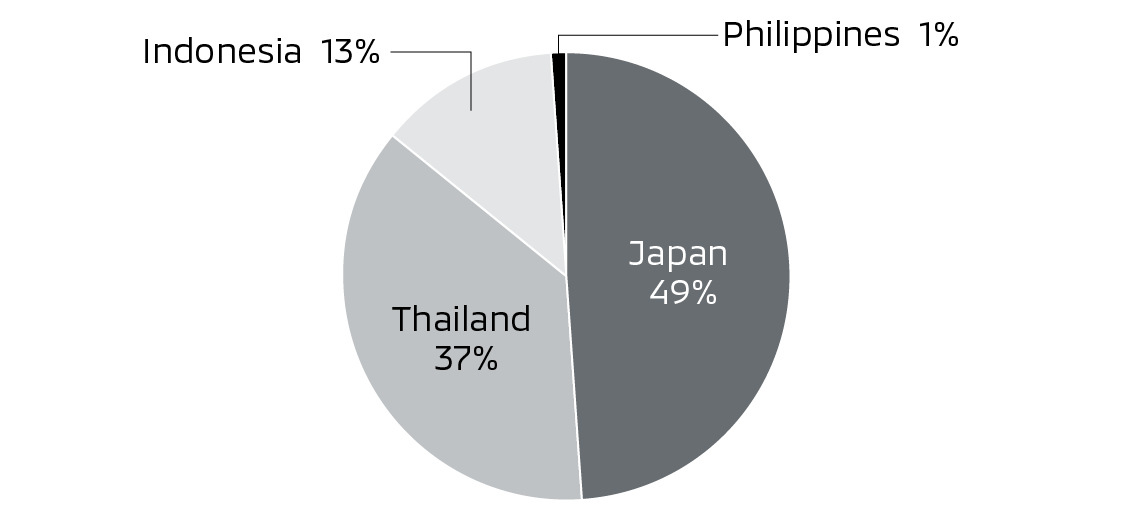

Country-Specific Parts Procurement Ratios by Production Base (FY2024)

To optimize costs at our overseas production bases, our basic

policy is to source from local suppliers where possible, as long as

such procurement is effective and the necessary technologies

are in place. For parts which are already locally procured, we also

promote the local procurement of the components used within

these parts, etc., to optimize costs further.

We conduct advanced audits of the systems and structures

of new business partners, evaluating items such as their

development capabilities, production capabilities, and quality

management capabilities, and issuing improvement instructions if

necessary. We also provide support to local business partners by

serving as a go-between with Japanese business partners, joint

ventures with local business partners, technical partnerships, and

the like. We work to contribute to local regions by creating local

jobs and improving local technical capabilities.

Employee Education and Training (Non-consolidated)

| Scope | Overview |

|---|---|

| All employees |

|

| Procurement divisions (Entry-level employees, mid-career hires, personnel transferred from other divisions) |

|

Participating in Outside Initiatives

- Japan Automobile Manufacturers Association, Inc.

- Partnership-building Declaration