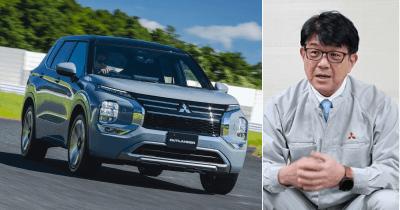

How exactly are Mitsubishi Motors cars made? At each step in the series of processes from research to planning, design, engineering, prototyping, testing, purchasing, production, distribution, and sales, there are professionals with highly advanced skills overseeing each respective process. In this series, we feature individuals from Mitsubishi Motors worksites. This is the second edition focusing on painting in production at plants. (The first edition is here)

Making workplaces more comfortable leads to better quality

In 1991, Kenji Suzuki was certified for all processes on the sealer team and became a leader. After that, he built his career as head of the team in 2001, and as assistant manager in 2011. His skills as a painting craftsman became unmatched. His biggest break came when he was recommended for certification as Master Trainer, a path to becoming a leader who passes on skills to others. In 2018 he successfully passed the certification test after undergoing training on the recommendation of a superior.

Mitsubishi Motors has its own original training system called the Manufacturing Dojo for passing on expert skills to the younger generation. There are a total of eight such dojos related to manufacturing, including for plating, welding, painting, and assembly, and only those with Master Trainer certification are appointed as the dojo masters. Suzuki became the master of the painting dojo at the Pajero Manufacturing plant of a Mitsubishi Motors affiliate in April 2018, then master of the painting dojo at the Okazaki Plant in September 2021. Incidentally, the dojo in Okazaki was established in 2006, and Suzuki became its fourth-generation master.

“In the past, the main approach to learning was to watch and try to physically imitate others, but these days it’s important to teach in greater detail. In the practical training at the dojo, trainees start by watching a video that teaches them about the work procedures, and then I actually perform those procedures myself. I teach them attentively about arm movements when painting such as the angle and positioning of the arms and how much strength to use, and give them tips for effectiveness while helping them develop intuition using their five senses.

Lessons at the dojo are given to people selected from each of the painting teams. Starting with introductory level courses for new employees, there are also intermediate courses for mid-career and veteran employees, plus advanced courses for those with high proficiency.

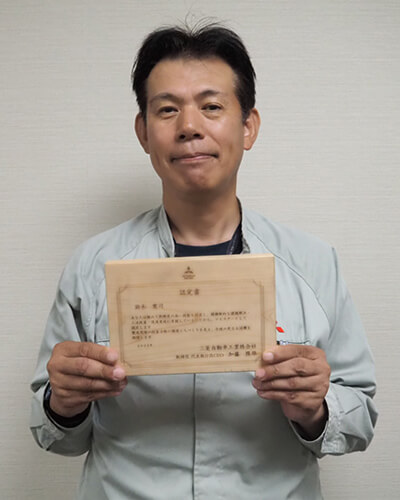

Suzuki and the Meister Certification

“Some of the advanced courses are for fixing paint, and for painting metal. It involves the manually-performed painting steps of priming, top coating, and clear coating, and we check the thickness. Only an extremely thin layer of overall layer of paint is actually allowed, with thickness about 0.1 mm. It’s quite strict. If you paint too much, the paint will drip. Those who are capable of fixing paint have reached the level of visually recognizing how much paint is needed for the desired thickness.”

Suzuki was certified as a “Meister” in July 2022. The Meister system is an in-house system that recognizes highly skilled individuals in the company who help to solve problems and improve engineering processes in a cross-functional manner and who play roles in boosting quality and productivity while also developing their successors. There are Master Trainers in every department, but even at the Okazaki Plant there are only two Meisters. This title recognizes a craftsman in the true sense of the word, not only for skills but also for developing and training the next generation. What exactly is the distinctive character of Mitsubishi Motors?

“When you talk about the strengths of Mitsubishi Motors, people tend to point out four-wheel control and PHEV (plug-in hybrid electric vehicle) systems. If you’re talking about the Production Department where we work though, I would say that it’s about being a comfortable place to work. The production worksites continue to evolve. In the past they were what people called the three K’s—kiken, kitanai, kitsui (dangerous, dirty, and demanding). However, various improvements have been made through efforts toward better workstyles, and nowadays the production processes are increasingly people-friendly. We also have training for safety, quality, and legal compliance, and these are becoming instilled. In the Vehicle Production Department, we remind ourselves on a daily basis that safety, compliance, and quality are our top priorities. Through our adaptations to these changes, our workplaces seem increasingly comfortable. I think that it benefits vehicle development and also the company in various ways when we have a comfortable place to work. In terms of communication, it brings about more openness in the organization which makes it easier to identify and solve problems earlier on. This type of thing is also important for passing on vehicle development skills and expertise. It should help to maintain the quality of our cars and lead to even more improvements.”

Suzuki served as master of the painting dojo at the Okazaki Plant for three and a half years until his transfer to a new department in April 2025.

“When I joined the company, the foreman of my team was my mentor. I tried my best to be like that person. In addition to workmanship, that foreman was also a good communicator who spoke to us about various things. I thought, ‘Wow, this is the type of person I want to be.’ I’m still not quite there yet. There are many things I must learn.”

Being a better leader and passing down advanced skills

Through his work in the paint “fixing” team, from 1999 onward Yoshihiro Ochi came to specialize in top coating, the last of the painting processes which is said to be a job that many aspire to. Former master of the Okazaki Plant painting dojo Suzuki recognizes Ochi’s skills as, “unmatched at top coating.” However, Ochi came to learn about the intricacy of top coating skills through the work itself. It is said that the distinctive character of Mitsubishi Motors lies in these skills.

“The distinctiveness of Mitsubishi Motors covers a wide range of things, but one of them is dedication. Since the old days, there have been many dedicated people in painting at this company. Japan has four distinct seasons, and we must be sensitive to changes in weather. The workers in each team dedicatedly employ different painting styles for summer and for winter, and paint one way on clear days and another way when it rains.

“Particularly in spring and fall. Mornings are cold but afternoons are warm, and the tone of the paint differs according to the time of day. The condition of the painted surface layer (finish) also differs. Everyone has their own way of dealing with it. Painting still seems to be a skill with a great deal of intricacy and no right way of doing it.”

Now, there are also painting processes that are mechanized and automated, but not 100%.

“Machines only do what they’re told. Humans have five senses, and we perform work based on these senses, so ultimately, the abilities of humans are also needed. It might be ideal to automate everything, but robots are incapable of the little things such as blending paint according to changes in temperature and humidity At the Okazaki Plant, tests for top coating are performed by visual inspection. On some days, you just feel like something is different from yesterday.”

Visually checking the condition of top coating

Ochi forged a singular path as a paint craftsman, but he then reached an age at which he would be passing on his defining skillset to the younger generation. In May 2024, he was certified as a Master Trainer to become a dojo master. Then, he became master of the painting dojo at the Okazaki Plant in April 2025.

“At that time, when I told my father that I would be dojo master, he nearly fell over laughing. It was hard for him to believe that I would take the same path as him. He told me that people in the company had helped me get to where I was, so it was time to pay it forward by devoting myself to others.”

Ochi was poor at speaking in front of other people, but joining the company was said to have “turned him around 180 degrees.”

“Starting about 5 years after joining the company I reached the point of teaching others as a leader, but the new employees were not producing much in terms of results after I taught them. It was depressing that I had tried so hard but couldn’t accomplish anything. However, when I myself took one particular training, someone told me that ‘Not being able to teach is the teacher’s responsibility.’ Then it hit me quite clearly.”

“At that point, I adjusted my teaching style in my own particular way. If you think about it rationally, each person has their own individual characteristics. When considering how to move forward, that helped me realize that instead of teaching by the book from A to Z, I also needed to go the extra mile of figuring out each person’s tendencies and make adjustments for them.”

“Mitsubishi Motors has lots of promising young employees. Many of them have not yet realized their potential, but how can you help them turn that potential into output? Teaching styles in the past were one-way , but I want to change that into a more two-way, interactive style. I think that communication is better and skills are understood more easily with a two-way teaching style. It would make me happy if they could capture some type of inspiration and channel it into professional growth at the Manufacturing Dojo.”

Ochi at the painting dojo teaching the physical movements for applying sealant

The outstanding skills of technicians trained at the Manufacturing Dojo support the production of Mitsubishi Motors cars. Based on what Suzuki and Ochi had to say, it seems clear that passing on these skills to other employees energizes them and simultaneously helps to create the distinctive character that sets Mitsubishi Motors apart.