How exactly are Mitsubishi Motors cars made? At each step in the series of processes from research to planning, design, engineering, prototyping, testing, purchasing, production, distribution, and sales, there are professionals with highly advanced skills overseeing their respective processes. The series beginning with this issue will feature individuals from Mitsubishi Motors worksites. This first edition focuses on painting in production at plants. It will be divided into two parts.

Taking on challenges, overcoming adversity and using it to his advantage

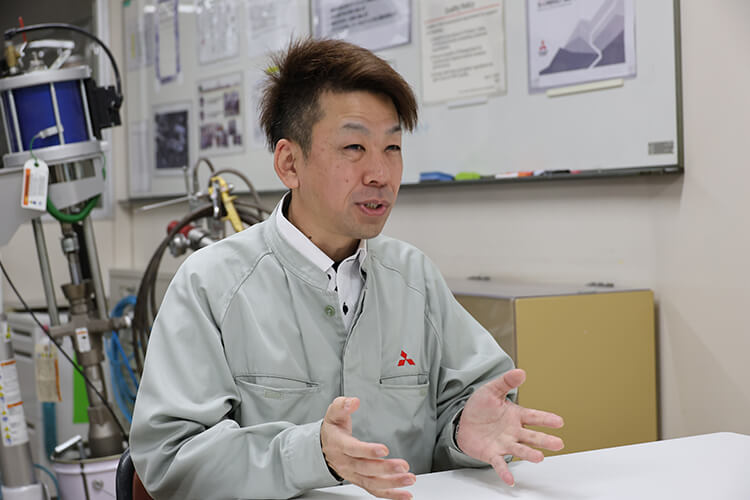

For roughly 40 years since he originally joined our affiliate Toyo Koki (later renamed Pajero Manufacturing* ), Kenji Suzuki has been singularly focused on painting. In recognition of this extensive experience and his outstanding skills and leadership, he was appointed as the fourth painting dojo master at our Manufacturing Dojo in September 2021. Since 2006, the Manufacturing Dojo training system has aimed to further bolster the competitiveness of Mitsubishi Motors manufacturing by ensuring that the specialized knowledge and outstanding skills of our expert employees are passed on to the next generation. At first, we asked Suzuki to share his experiences, starting with how he joined the company to begin with.

“Back when I was in school, Mitsubishi Motors models such as the Starion and first-generation Pajero were massive hits. They also made me want to drive them, which inspired me to join an automotive-related company. There just happened to be a Mitsubishi Motors affiliate near the house where I grew up (in Mizunami, Gifu Prefecture), so I wanted to joine that company.”

That was in April 1986. He was assigned to the painting shop. Out of the 200 people hired for plating, painting, and assembly, 20 went to the painting shop. Suzuki has spent his entire career to this point in painting, but that was not his intention when he joined.

“I sort of liked the idea of working a job related to assembly. However, just put my head down and tried my best to fulfill the role expected of me, in the workplace where I was assigned. Painting processes for cars are now almost fully automated, but in the old days there were eight painting craftsmen tasked with painting each individual car by hand. Since there were so many painting specialists, it was also highly esteemed work in a technical sense. Work was nonstop back then. It was normal to work three hours of overtime each day, and to also work on Saturdays. Driven to catch up to my veteran colleagues and be like them, I started out by just trying to handle each task immediately in front of me the right way. With that sense of determination, I gave it my all.”

Even so, there were a few failures along the way before he could become an elite craftsman. Here is one of them.

“I was 21 or 22 years old then. I was working exclusively on the sealer team (the team that applies sealant to the adjoining parts and seams of the car’s body panels for waterproofing and anti-rust purposes) and had been put in charge of the roofing process to apply sealant to the roofs of the cars. On that job, I caused a rain leakage defect. A gap formed at a seam, and water ended up leaking into the car.”

“Where this occurred, the rain leaks would first appear when the car went onto the shower test line. I ended up leaving the rain leakage defect in eight consecutive cars. The shock from that even haunted me in my dreams. People were strict to each other in those days, and I got yelled at quite harshly.”

“When that happened, I wondered whether sealant could be applied in a way that leaks never occur regardless of who applies it, and I worked on modifying the nozzle of the sealant gun. Through trial and error, I changed the length and modified the tip of the nozzle. From that experience I learned it was possible to improve work efficiency, and after that I gained the ability to propose various improvements to the company.”

While “painting” may be one simple word, there are a number of processes involved. In order, these are pre-treatment and electrocoating (initial priming that uses electrical current to apply coating), sealing, sanding, middle coating, top coating (also clear coat if metallic), drying, and inspecting (touch-up polishing). Having mastered all of these skills, Suzuki can probably be considered an elite professional. In painting, where does the difficultly lie?

“Painting protects the body of the car from damage such as scratches and rust caused by the sunlight (ultraviolet light) and weather (acid rain) it will be exposed to, making it last longer. Therefore, you cannot make beautiful cars that people admire if the quality of the painting work is less than excellent.”

“For example, when applying paint by hand spray, you need to spray at a constant speed while maintaining a set distance between the spray gun and the part being painted. Thus, it requires skill. With a robot you can keep a preset distance while painting, but when a human does it, any variations in distance can cause the color to change. However, even now there are still processes that must be painted by hand such as the insides of doors. If someone trains at painting every day, they will be able to do the job after about a month. That’s at the beginner level. They will still not be a full-fledged professional yet. Getting to that level requires more seasoning.”

Openings in the car body being painted by hand spray, since these areas must be painted manually

Seeking uncompromising quality in every single vehicle

Yoshihiro Ochi specializes in top coating, the last of the painting processes which is said to be the biggest focus of attention. He has been master of the painting dojo since April 2025 when Suzuki, the fourth painting dojo master at the Okazaki Plant, handed him the baton. He is working on training and developing the next generation. Coincidentally, Ochi’s father had also served as master of the welding dojo at the Mizushima Plant.

“In high school I competed in wrestling, and when I advanced to the national tournament I was approached by a university with an offer for priority recommendation for admission. However, they told me that they wanted me to acquire a teaching license and coach the subsequent generation after I was done and graduated. Since I was not good at speaking in front of others, I declined their offer and thought about entering the workforce without going to university.”

“Since I am from Kurashiki in Okayama Prefecture and my father was dojo master at the Mizushima Plant, naturally I think that I grew up watching and being influenced by him. I also liked cars, so Mitsubishi Motors was really the only option for me. Since I was a child, various acquaintances of my father from the plant came to our house and looked after me, so Mitsubishi Motors was a company that felt like family.”

He joined the company in April 1996. His assignment was in the painting section. For the first three years, he worked on fixing painting defects in finished cars.

“Fixing paint is a lonely task, so it seemed like something I was well suited for. They would request that I fix a certain area of a car that got damaged in the assembly process, but the location of the damage on the car was never the same. Just keeping quiet and going about work matter-of-factly seemed to be my calling.”

The words of a mentor that Ochi met back then became the foundation for his life as a craftsman.

“When painting cars one at a time, I started to always think ‘What would I do if this car were mine?’ The company might manufacture 500 cars per day, but from each customer’s perspective it’s their one and only car. It was my first mentor who taught me that. I often heard it when I was around 19 or 20. It would go like this. ‘If you mess it up, buy the car yourself.’ ‘I can’t.’ ‘Well, a customer is going to get it, so don’t cut corners them' like that.”

“It was someone around my father’s age who was friendly with him but didn’t talk much. Being someone from that era, this was a craftsman who expected me to learn by following and watching. This mentor has skills that everyone recognizes and never fails. There were many veteran colleagues who taught me things, but I decided to learn from this person. I didn’t just tag along mindlessly. I followed him around and watched how he performed every little task. People these days need to be taught clearly and attentively, but I came up in an environment where you had to think things through yourself when you failed.”

Kenji Suzuki and Yoshihiro Ochi both learned many lessons through their careers dedicated to painting, which molded them into elite professionals. How can the outstanding skills they possess be passed on? Mitsubishi Motors has its own original training system called the Manufacturing Dojo. In the second part, Suzuki and Ochi share their insights about teaching the next generation.

* The company that manufactured models including the Pajero and Delica D:5 until August 2021.