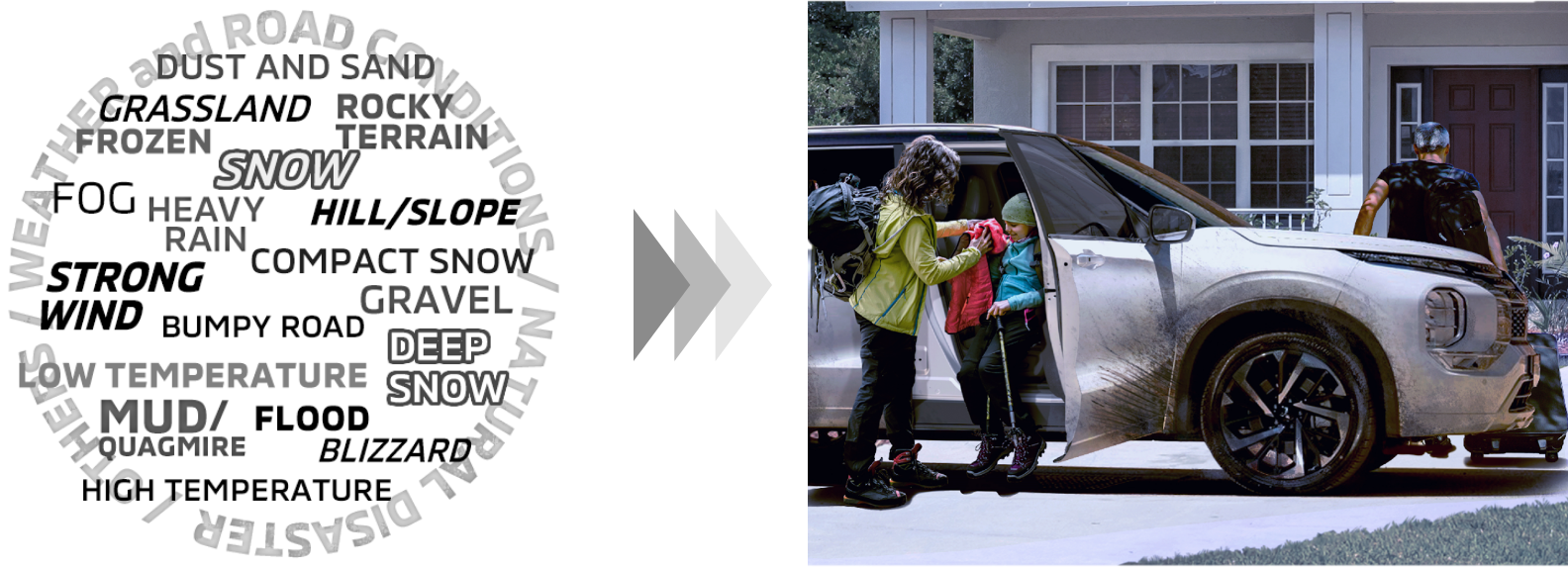

Reliable durability

Drawing on design principles cultivated in diverse environments and road conditions worldwide, Mitsubishi Motors aims to develop durable vehicles that customers can depend on to bring them home safely, no matter the conditions they encounter.

Development team’s philosophy

Strength that holds up anywhere in the world

We want our customers to feel secure going wherever they wish, and want to provide them with vehicles that spark their sense of adventure. 'Returning safely from any adventure' is a major theme, and we consider it our mission.

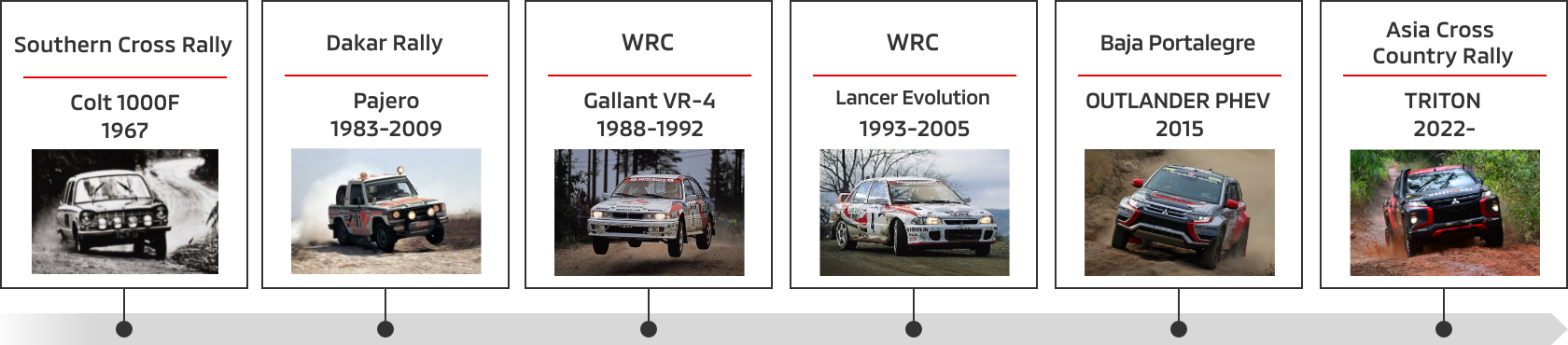

History

Mitsubishi Motors has long participated in rally racing with vehicles based on production models. Since our sensational debut at the Southern Cross Rally, we have achieved seven consecutive wins in the Paris-Dakar Rally, the world's toughest motorsport, and have made our mark in the WRC. We have also participated in the Asia Cross Country Rally in recent years, continuing to take on challenges. The technologies and insights gained from motorsports are fed back into production, allowing us to offer customers durable and reliable vehicles.

Rigorous testing

World-class testing standards

Mitsubishi Motors collects data on usage environments and road conditions from around the world. At our Research & Development Center in Okazaki, Aichi Prefecture, and our research facility in Tokachi, Hokkaido, we have courses and testing facilities that replicate the world's harshest environments and roads. There, we conduct rigorous tests daily and feed the results back into our designs.

Our rough road durability tests focus on real-world driving to rigorously strengthen the vehicle’s body and enhance durability.

durability test

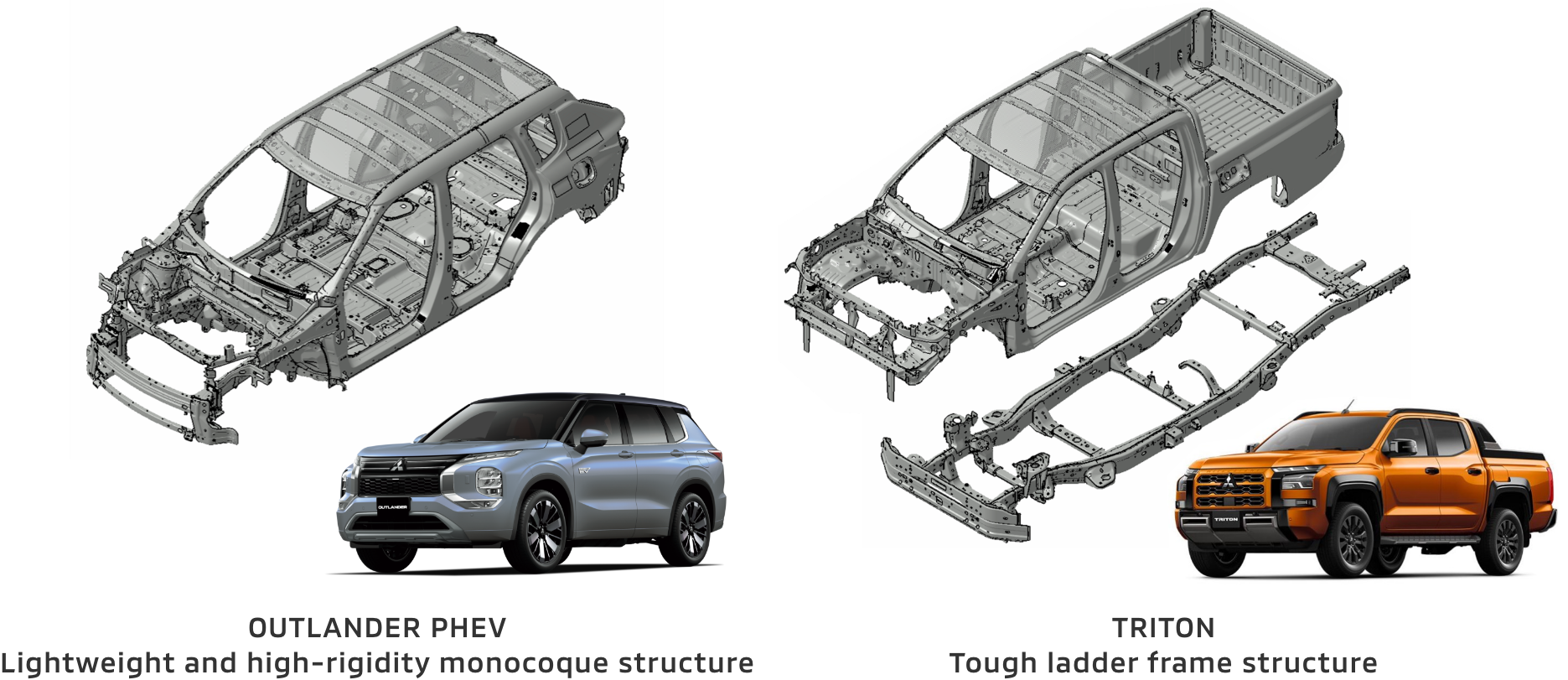

Tough, rugged structure

A robust body that provides both safety and an enjoyable driving experience

The body not only provides space for passengers and cargo but also features an exceptionally strong and robust structure to help protect passengers in the event of a collision. A highly rigid body also improves handling and ride comfort, providing an enjoyable driving experience to customers.

The right material in the right place

Environmentally friendly

In response to the growing issue of global warming, we are working on reducing CO₂ emissions by making vehicle bodies lighter. We use lightweight materials such as aluminum and high-tensile steel panels where appropriate, aiming to balance body strength and weight reduction. Reducing the weight of the vehicle body also reduces the load on chassis components, which enhances durability. Additionally, by improving the basic functions of accelerating, turning, and braking, we ensure that the vehicle handles just as the driver intends, making it fun to drive.

Vehicles that pass strict standards excel in rigorous environments

Examples

Examples

vehicles are used daily in rigorous

environments such as mines

world to provide support