Today, the plug-in hybrid electric vehicle (PHEV) model of the Outlander has become the flagship model of Mitsubishi Motors. When originally released in 2013, it established the new category of a PHEV crossed with an SUV, which was unlike anything before in the automotive world.

However, its development had been far from smooth. The development team which created the world's first-ever mass production electric vehicle (EV) the i-MiEV had started development of a new EV in the SUV category, but their efforts had stalled. Regardless, the team never gave up the pursuit of their ideal vehicle.

How did the development team eventually arrive at the PHEV? Together with Kazunori Handa, a member of the EV and Powertrain Advanced Engineering Development Department and the development team of EVs at Mitsubishi Motors since 1994, this series looks back on the development of the PHEV. Part 1 is "The Dawn of the PHEV."

Kazunori Handa,

EV and Powertrain Advanced Engineering Development Department

While cars have made our lives more convenient and fulfilling, the noise and exhaust they produce while driving have also negatively impacted cities and the environment. Tireless efforts by automakers have led to continuous improvements over the years, but the last challenge that remains is CO2, a major driver of global warming. As the trump card for significantly reducing CO2 emissions, eyes have now turned to EVs which run on electricity and produce no CO2 emissions while driving.

It was 1964 when Mitsubishi Motors began working on development of EVs. Development proceeded, and in 1994 the Libero EV featuring a lead acid battery was released as a vehicle for electric power companies. However, its road performance came nowhere close to that of gasoline-powered vehicles. Looking back on those times, Handa remarks that the problem with EVs at the time was the lead acid battery.

"Half the vehicle weight of the Libero EV was its lead acid battery. It was very heavy, and we struggled getting the car to run. Since EVs also have to be charged often, it was nothing more than a 'bothersome car that doesn't run' from the perspective of our customers."

The vehicle that drastically changed Handa's thinking was the prototype of the i-MiEV, for which development started in 2005. Adopting the lithium-ion batteries used in many small consumer electronics products such as mobile phones and laptops reduced the weight of the battery, which successfully led to a significant reduction in vehicle weight. This was when the unique road performance of a pure EV powered entirely by the electric motors was finally unveiled.

"It takes off with a 'whoosh' the moment you press the accelerator. The smooth, powerful ride without any noise or vibration was completely different from the driving performance of gasoline-powered cars. I remember that I was very enthusiastic about the development, because I thought that Mitsubishi Motors might be able to develop cars with even better environmental performance* than anything before. We wanted to share this excitement with as many people as possible, so we held one test drive event after another. Even those who seemed anxious about whether the i-MiEV could run properly before driving it ended up with smiles on their faces when they got out."

Also, 2005 was the year in which the Pajero Evolution became the first ever to win five consecutive and 10 overall victories in the Dakar Rally (officially 2005 Telefonica-Dakar Rally). While the entire development department of Mitsubishi Motors was excited to meet expectations of customers for Mitsubishi vehicles that are safe, secure and comfortable on any road conditions, the development of EVs was never in the mainstream. Despite that, engineers who had taken the challenge to develop EVs were confident in their potential.

"Cars that anyone can drive easily, comfortably, and with peace of mind, and that have no impact on the environment, are sustainable, and offer the joy and convenience of driving – our ideal goal is to provide cars with that standard of comfort, security, safety and environmental-friendliness. Such ideal vehicle that is fun to drive and eco-friendly becomes possible with EVs. That was the reason we mass produced the i-MiEV, and our beliefs now are the same as then."

In 2009, Mitsubishi Motors finally began mass producing the i-MiEV. It earned strong recognition not only for emitting no greenhouse gases while driving, but also for its smooth, powerful ride that puts smiles on the faces of everyone aboard.

Libero EV

i-MiEV

Lithium-ion batteries as the obstacle on the path to developing a next generation EV

Mitsubishi Motors began developing its next generation EV in 2007, two years before starting mass production of the i-MiEV. The target was the SUV category, Mitsubishi Motors' core line of vehicles which had generated famous models such as the Pajero. However, the path toward that goal was anything but smooth.

"Higher-performance batteries would be needed to power a car larger than the i-MiEV with electricity. On the other hand, larger batteries would weigh down the body of the vehicle, and installing the battery would also require space. Batteries then were also far more expensive than they are now. At the time, the movement to make EVs more mainstream had only recently begun, so battery manufacturers were not yet considering the mass production of batteries large enough to power cars. We predicted it would take around 10 to 15 years for battery performance to improve and prices to fall."

People who drive SUVs are often outdoors enthusiasts who want to drive long distances and load the vehicle with lots of cargo and passengers. Conversely, those who choose EVs want to enjoy the smooth, powerful acceleration of electric motors, whether driving along the coast or in the mountains. In order to meet all of these requirements at the same time, the best solution would be to develop a distinctively Mitsubishi EV that is highly durable, easy to use, and fun to drive as an SUV. However, it was not possible to develop such electric SUV with the performance level of batteries at the time.

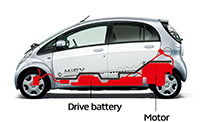

i-MiEV

Drive battery

The PHEV Was the Answer to Make the Ideal Vehicle

Still, the engineers at Mitsubishi Motors never quit. They kept going, based on the idea that, "The EV is like a flower bud that will someday bloom magnificently. However, it will only wither away if we don't nurture it now." How could a bridge to the future of EVs be built? The answer that the Mitsubishi Motors development team produced for this conundrum was the PHEV.

PHEVs are equipped with generators and engines to generate power in order to extend their range, which had previously been the weakness of EVs. With an EV as its base, the PHEV is mainly powered by its electric motors. This meant it could be used as an EV in nearly all daily driving scenarios, and a balance was thereby achieved between clean driving with zero CO2 emissions and the powerful road performance particular to electric motors. At the same time, when battery power runs out on longer drives, it can be recharged by the power-generating engine, virtually eliminating any concerns about running out of power. The PHEV can also drive primarily by the engine when at high speed.

"In terms of eco-friendliness as well, PHEVs are in no way inferior to EVs. CO2 is produced when generating the electricity used while driving, when producing the car, and when disposing of the car. CO2 emissions are particularly high when producing the car batteries. The higher capacity the battery, the more CO2 is emitted. On the other hand, the engine does not involve particularly high CO2 emissions in production, but it emits relatively more CO2 while driving.

The concept of CO2 reductions with the PHEV is to curb CO2 emissions during production by making the volume of the equipped battery just sufficient for everyday driving, while also emitting less CO2 by driving as an EV in higher-frequency driving scenarios. PHEVs also receive the highest eco-friendly estimations in the Life Cycle Assessment (LCA) method to calculate the environmental impact of a vehicles' entire life cycle (raw material procurement, manufacturing, use, recycling, and disposal)."

Having developed mass-production EVs before anyone else, Mitsubishi Motors had batteries that could ensure sufficient range for city driving, as well as motors that deliver superior driving force. The development team was confident that if they could add the four-wheel control technology onto this tremendous advantage, they could get even closer to the ideal vehicle that offers the joy and convenience of driving along with sustainability and no impact on the environment.

"Drivers cannot get to faraway mountains or the coastline with the i-MiEV battery alone. However, if the motors could be powered by electricity generated by the engine on roads such as expressways leading toward those destinations, the problem with charging capacity could be solved. The PHEV was developed with the idea of driving as an EV in the areas where you want to drive an EV, and covering longer distances between those areas with the engine."

The engineers thus began their quest to develop the PHEV.

Outlander PHEV (first generation)

⋆Environmental performance: Indicates performance in energy-saving and other related areas for cars and other artificial objects, such as whether they perform comparatively better than other products at reducing their impact on the environment when manufactured and used, and whether they can be used in an energy-efficient manner. Cars with low or no emissions in particular are often referred to as having high environmental performance.