Focusing on lithium-ion cells, previously the leading choice for small batteries

Project Development Management Department,

Makoto Kishi

Development coordinator for mass-production vehicles.

From around 2006,

he handled i-MiEV, and thereafter EV Kei-cars.

Mitsubishi Motors' research efforts in the EV space date back to 1966, when automobile manufacturing was still one business of Mitsubishi Heavy Industries. The 1970s saw the development of the Minica EV and Minicab EV. In 1990, following the State of California's enactment of ZEV (Zero Emission Vehicle) regulations requiring automakers to sell a certain amount of ZEVs, we stepped up our EV development, but batteries proved to be a key hurdle. The lead-acid batteries used at the time were heavy, accounting for about half of the vehicle's weight. Moreover, battery capacity depended heavily upon on how the vehicle was used, meaning that range was not stable. The development staff at the time, who was then working on EV development, said, "We became acutely aware of the limitations of lead-acid batteries, both in terms of cost and performance.With lead-acid batteries, range varies greatly depending on how the vehicles are used. In 1993, we sold the Libero EV, a 100% electrically-powered vehicle, to government agencies and corporations, but we were flooded with complaints along the lines of 'Why can't I go today where I was able to go yesterday?'"

Libero EV

As the development of new batteries emerged as a pressing issue, we turned our attention to lithium-ion batteries.

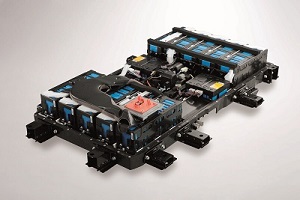

Lithium-ion batteries, while light and compact, have very high energy density. Although they went on the market in 1991, at that time, only small batteries for cell phones and PCs were manufactured. There were no companies willing to cooperate in the development of a large battery that could be used in EVs, but after much searching, we finally found a partner that was interested and willing to corporate in developing a larger lithium-ion battery.

In 1995, the Mitsubishi HEV, a plug-in hybrid vehicle equipped with lithium-ion batteries, reached completion. With a range of 60 miles (approx. 96 km), it took the world by surprise. It was scheduled to undergo operational trials by the California Air Resources Board (CARB), but our staff in the U.S. informed us that the car had caught fire. It was then discovered that the battery had been overcharged as a result of using a high-voltage charger for lead-acid battery, causing it to ignite.

To address this issue, we developed a battery management unit that could control not only transmission voltage, but also cell voltage and temperature. In October 1996, the new Mitsubishi HEV passed the CARB operational trial.

Mitsubishi HEV

Subsequently, We began developing lithium-ion batteries for mass-production with Japan Storage Battery (now GS Yuasa Corporation), and by 1999, batteries with a large capacity of 95 Ah had been developed. The FTO-EV equipped with these batteries could be quickly recharged in 20 minutes and provide speeds of 130 km/h. It also ran for a total of 2,142 km, smashing the previous Guinness world record of 1,700 km.

urthermore, we developed prototypes for Colt and Lancer Evolution EVs equipped with lithium-ion batteries, aiming to explore Mitsubishi Motors' future vision for electrically-powered vehicles.

Colt MIEV

Lancer Evolution MIEV

Combining control techniques developed in rallying with electric technology

In 2005, our development of EVs picked up speed. Makoto Kishi, from the Product Development Division's Project Development Management Department, says he remembers the call from the executive as if it were yesterday.

"With the adoption of the Kyoto Protocol in 1997 and a growing awareness of environmental issues, I believe that our management team had a strong sense that we, as an automaker, had a mission to develop EVs for mass-production. In the fall of 2005, I received a phone call out of the blue from an executive who said, 'We are going to launch the world's first mass-production EV. You can stop all the work you are doing now — I want you to manage that project.' I had thought that EVs would not be mass-produced for some time yet, so this came as quite a surprise."

This was a time when other automakers were also researching EVs, but none were moving toward mass production and sales. However, Kishi felt that the technical hurdles were not unduly high.

"Because of their high energy density, lithium-ion batteries can be dangerous if used incorrectly. — How can we control the electricity flowing to the motor as desired? — How can we ensure safety until the moment the battery is used up? Having started early, we had the advantage with respect to these issues."

The fact that Mitsubishi Motors had continued to refine its technology for safe and enjoyable driving also made a positive contribution to its EV development.

"For example, if torque increases suddenly when accelerating with the motor, the driver will feel discomfort, and it will be a difficult car to use. So, how could we make a car fun to drive while taking advantage of the motor's unique characteristics? We had been refining our motor control techniques by modifying fun-to-drive production vehicles like the Colt and the Lancer Evolutions. That is how we were able to combine our EV control techniques with the technology we had developed in rallying and the like."

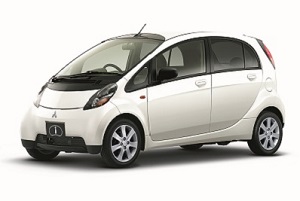

The car chosen as the base vehicle was the i. As a rear-wheel drive minicar, the engine was mounted under the luggage area to shorten the nose, and the fuel tank was located under the cabin. Other features of the i included its long 2,550 mm wheelbase (the length between the front and rear axles) and its large interior space.

"The difficult part of EV development is placement of the large, heavy battery. The i's long wheelbase allowed the space under the cabin floor, where the fuel tank was originally, to be extended. This meant that the motor, transmission, inverter and on-board charger could be laid out in the engine room. It was the perfect platform for an EV."

i

A world-first made possible by management's will being instilled throughout the company

In 2009, the mass-production EV, i-MiEV, was finally introduced to the market. With the same generous interior space and loading space as the i, the i-MiEV maintained its ease of use. The motor provided a maximum output of 47 kW (64 PS) / 3000 to 6000 rpm, a maximum torque of 180 N·m (18.4 kgf·m) / 0 to 2000 rpm, and a maximum speed of 130 km/h. The lithium-ion battery offered total power capacity of 16 kWh and total voltage of 330 V, with a range of 160 km on a full charge in the 10–15 mode, sufficient for everyday use.

i-MiEV

Lithium-ion battery

Motor

What surprised the market more than anything else was the i-MiEV's quiet, peppy ride. It also offered the silence and comfort that only an EV can provide. By taking advantage of the properties of electric motors, which give quick feedback and generate high torque from low speeds, it delivered a responsive and powerful driving experience.

"The reason we were able to sell the i-MiEV almost exactly on the originally planned schedule is because we shared a company-wide belief that Mitsubishi Motors would be the first in the world to launch an EV. The Model T Ford, the world's first mass-produced car, first went on sale in 1908. The fact that 100 years later, we would change the history of automobiles by selling mass-produced EVs is the result of management giving the order and that order resonating throughout the company. At first, some people at the Mizushima Plant, which had previously manufactured only gasoline and diesel vehicles, said there was no way they could make EVs on the production line, but after frequent visits and discussions, everyone took a positive attitude toward the project. I think that is why we were able to establish EV production technology earlier than anywhere else."

Kishi and the rest of the EV development team were dead set on carrying the EV technology they have developed into the future. The EV torch, which they kept alight over 13 hard years, would be passed on to the eK X ("cross") EV, which was announced in 2022.

eK X EV,i-MiEV, Minicab MiEV(From right)