Company History

Presented here is Mitsubishi’s journey in the

automobile industry since the company’ establishment.

Company History

Presented here is Mitsubishi’s journey in the

automobile industry since the company’ establishment.

View the history

of past cars

1870

Tsukumo Shokai (later Mitsukawa Shokai) was founded by the Tosa Clan, positioning Yataro Iwasaki as the manager.

1873

Yataro Iwasaki changed the company’s name from Mitsukawa Shokai to Mitsubishi Shokai, and became the company’s president.

1875

Mitsubishi Shokai changed its name to Mitsubishi Kisen Kaisha.

Mitsubishi Kisen Kaisha changed its name to Yubin Kisen Mitsubishi Kaisha.

1885

Yanosuke Iwasaki founded Mitsubishi Sha (later Mitsubishi Goshi Kaisha), and became the company’s president.

1893

Hisaya Iwasaki became president of Mitsubishi Goshi Kaisha.

1914

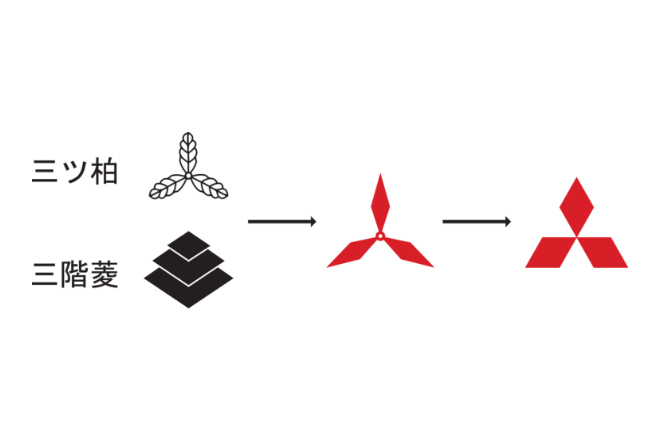

Mitsubishi registered its trademark (the three-diamond symbol).

Mitsubishi registered its trademark (the three-diamond symbol).

The symbol “![]() ” originates from the three-diamond emblem that Tsukumo Shokai used for its ship’s flag since it took over the shipping business from the Tosa Clan in October 1870.

” originates from the three-diamond emblem that Tsukumo Shokai used for its ship’s flag since it took over the shipping business from the Tosa Clan in October 1870.

It is said that the emblem is derived from the three stacked rhombuses which was the crest of the Iwasaki family, and the three oak leaves which was the crest of the lord of the Tosa Clan, the Yamauchi family.

The diamonds used to be required around 30-degree angle and then was changed to have 60-degree angle when the symbol was updated to be the present form in 1910. In March 1914, Mitsubishi Goshi Kaisha filed a trademark application with the Patent Office, and the symbol was registered as the company’s trademark in June of the same year.

Later on, as the company diversified its business, the use of its new enterprises’ name “Mitsubishi” as well as the three-diamond symbol spread. MITSUBISHI MODEL A, Japan’s first mass-produced passenger car completed in November 1918, also bore this emblem on its radiator grille.

Prev

Next

1916

Koyata Iwasaki became president of Mitsubishi Goshi Kaisha.

1917

The Shipbuilding Division of Mitsubishi Goshi Kaisha becomes the independent company Mitsubishi Shipbuilding Co., Ltd.(later Mitsubishi Heavy Industries, Ltd.)

1920

Mitsubishi Internal Combustion Engine Mfg. Co., Ltd. established Nagoya Plant.

Mitsubishi Internal Combustion Engine Mfg. Co., Ltd. established Nagoya Plant.

Mitsubishi Internal Combustion Engine Mfg. Co., Ltd. (later Mitsubishi Heavy Industries, Ltd.) established the Nagoya Works (later Oe Plant) on the land reclaimed from the sea beyond Higashitsukiji, Minami Ward, Nagoya, Aichi Prefecture (current address: Oe-cho, Minato Ward, Nagoya) to manufacture aircraft fuselages. After World War II, the plant switched to the manufacture of motor vehicles in order to meet private-sector demand. The plant began manufacturing Silver Pigeon scooters in 1946, and four-wheel-drive vehicle Mitsubishi Jeeps in 1952.

In August 1977, Mitsubishi Motors established its first plant, Nagoya Motor Vehicle Works - Okazaki Plant, in Hashime-cho, Okazaki, Aichi Prefecture. The company manufactured motor vehicles at this plant and the Oe Plant in the Nagoya area since, but in 2001, it closed down the Oe Plant.

In October 2016, Nagoya Works was renamed Okazaki Plant, and today, the plant manufactures automobiles, mainly sport utility vehicles (SUVs).

The Nagoya area has also been the development base covering from basic research to product development. The Okazaki test track was completed in 1962, and the Mitsubishi Motors Technical Center (currently Research & Development Center) was established in Hashime-cho, Okazaki, Aichi Prefecture in 1969.

Furthermore, in April 2012, the EV Research & Development Center was established for electric vehicle development in Nikki-cho, Okazaki, Aichi Prefecture.

Prev

Next

1943

Mizushima Aircraft Plant (currently Mizushima Plant) established by Mitsubishi Heavy Industries, Ltd.

Mizushima Aircraft Plant (currently Mizushima Plant) established by Mitsubishi Heavy Industries, Ltd.

Mitsubishi Heavy Industries, Ltd. established the Mizushima Aircraft Plant in the area beyond the Takahashi estuary (currently Mizushima Kaigan Dori in Kurashiki) in Tsurajima-cho, Asakuchi, and Fukuda-son, Kojima, Okayama Prefecture, to manufacture aircraft fuselages. After World War II, the plant switched to the manufacturing of motor vehicles in order to convert their technology to civilian use. The production of the three-wheel cargo carrier Mizushima was started in 1946, the mid-sized truck Jupiter in 1959, and the lightweight commercial vehicle Mitsubishi 360 in 1960.

In June 1999, Mitsubishi Motors changed the name of the plant from Mizushima Motor Vehicle Works to Mizushima Plant, which currently produces cars and engines, mostly light automobiles, as well as electric vehicles.

Prev

Next

1944

Kyoto Device Manufacturing Works (currently Kyoto Plant - Kyoto) established by Mitsubishi Heavy Industries, Ltd.

Kyoto Device Manufacturing Works (currently Kyoto Plant - Kyoto) established by Mitsubishi Heavy Industries, Ltd.

Mitsubishi Heavy Industries, Ltd. established Kyoto Device Manufacturing Works in Uzumasa, Kyoto (currently Uzumasa Tatsumi-cho, Ukyo Ward, Kyoto) to produce aircraft engines. After World War II, the plant switched to the manufacture of car engines and transmissions to civilian establishment. The production of the GB 38 gasoline engine was started in 1946 and the KE 5 diesel engine (“KE” stands for Kyoto Engine) in 1949.

In December 1979, after the founding of Mitsubishi Motors, the company established Kyoto Works - Shiga Plant in Kosei-cho, Koga, Shiga Prefecture (currently Kosuna-cho, Konan). Today, the Kyoto and Shiga Plants produce car engines.

Kyoto Works was renamed Powertrain Works in June 2003, and then renamed again Kyoto Works in April 2017.

Prev

Next

1949

Established a truck and bus distributor, Fuso Motors Sales Co., Ltd.

1950

Mitsubishi Heavy Industries, Ltd. split into 3 companies.

1952

Companies including the three Mitsubishi Heavy Industries companies moved their headquarters to Marunouchi in Chiyoda City, and began to use Mitsubishi’s corporate name and its three-diamond symbol again.

1954

Established Ryowa Motor Sales Company (later Shin Mitsubishi Motor Sales Company) as a distributor for domestically manufactured jeeps.

Established Ryowa Motor Sales Company (later Shin Mitsubishi Motor Sales Company) as a distributor for domestically manufactured jeeps.

In July 1952, Shin Mitsubishi Heavy Industries Co., Ltd. (the predecessor of Mitsubishi Motors) and Willys-Overland Motors in the United States signed an outsourcing agreement for knock-down assembly of Jeep. The first J1 Mitsubishi Jeep was completed in February the following year.

In July of the same year, Shin Mitsubishi concluded technical assistance and sales agreements with Willys-Overland to acquire the licenses to manufacture and sell Jeep in Japan. Following this license acquisition, Shin Mitsubishi and Kurashiki Rayon Co., Ltd. (currently Kuraray Co., Ltd.) jointly founded Ryowa Motor Sales Company as a seller of all the Jeep vehicles manufactured in Japan in May 1954. In July 1956, the production of the Japan made Jeeps was launched.

Asides from the Mitsubishi Jeeps, Ryowa Motor Sales Company began to sell the Jupiter, Rosa, and Mitsubishi 500. In May 1963, the company was renamed Shin Mitsubishi Motor Sales Company, and sold all lines of motor vehicles produced by Shin Mitsubishi Heavy Industries.

Prev

Next

1962

Okazaki Test Course completed at Nagoya Plant.

1964

The three Mitsubishi Heavy Industries companies merged to form the new Mitsubishi Heavy Industries, Ltd.

Established Mitsubishi Motor Sales Company.

Established Mitsubishi Motor Sales Company.

After World War II, Mitsubishi was broken up into three heavy industry businesses. In June 1964, these three merged to form new Mitsubishi Heavy Industries, Ltd. This merger integrated the production of large- and mid-sized trucks and buses by Mitsubishi Nippon Heavy Industries and scooters, light motor vehicles, passenger cars, mid- and small-sized trucks and buses by Shin Mitsubishi Heavy Industries under the umbrella of one brand.

Following this integration of the production departments, Mitsubishi Fuso Motors and Shin Mitsubishi Motor Sales Company explored the possibility of amalgamation to establish a large-scaled motor sales company handling all types of vehicles including scooters, light motor vehicles, and large trucks and buses. In June 1964, the two businesses’ board of directors approved the resolution to conclude a merger agreement, which specified that Mitsubishi Fuso Motors shall be the surviving company in the merger, and that the company’s trade name shall be changed to Mitsubishi Motor Sales Company.

The notice of the merger was submitted to the Japan Fair Trade Commission in August 1964, and the new company was launched in October.

Prev

Next

1965

Mitsubishi Heavy Industries, Ltd. acquired shares in UDMI of Thailand.

Mitsubishi Heavy Industries, Ltd. acquired shares in UDMI of Thailand.

Exports of Mitsubishi vehicles to Thailand began with large buses in 1952. In August 1961, Sittipol Motor Company (SMC) was established with local capital as a sales company for imported Mitsubishi vehicles. In the beginning, the three-wheeled light vehicle Leo was exported. The vehicles sold by SMC gradually increased in variety and number, including passenger cars and mid-sized trucks.

In the 1960s, Thailand promoted local assembly of vehicles to invite foreign capital, as an alternative policy for imported cars. Following this move, United Development Motor Industries Co., Ltd. (UDMI) was established with local capital in October 1964. Mitsubishi Heavy Industries, Ltd. began equity participation in UDMI the following year, and in June 1966, UDMI launched the production of Mitsubishi vehicles as the first local Mitsubishi car manufacturer overseas.

In December 1973, Mitsubishi Motors began equity participation in SMC that served as its local sales company. It operated its business in Thailand jointly with the local companies, with SMC being their seller and UDMI the manufacturer. These two companies merged in January 1987 to form MMC Sittipol Co., Ltd (MSC; located in Bangkok, Thailand).

In November 2003, to enhance sales and marketing strategies by unifying the companies’ names, MSC was renamed Mitsubishi Motors (Thailand) Co., Ltd. (MMTh), and has been in effect since then.

Prev

Next

1966

Dealers nationwide were crowned with the title of “Mitsubishi Motor Sales” in their corporate names.

1967

Production of jeeps fully outsourced to Toyo Machinery Co., Ltd. (currently Pajero Manufacturing Co., Ltd.)

Production of jeeps fully outsourced to Toyo Machinery Co., Ltd. (currently Pajero Manufacturing Co., Ltd.)

The Mitsubishi Jeep had been manufactured by Shin Mitsubishi Heavy Industries, our predecessor, since 1953. Later, the production was later fully outsourced to Toyo Machinery Co., Ltd. (then located in Kita Ward, Nagoya) as part of the streamlining project at Nagoya Motor Vehicle Works.

Toyo Machinery relocated its plant to Sakahogi-cho, Gifu Prefecture in September 1976. The company integrated manufacturing of Pajero, which originated from the Mitsubishi Jeep, in February 1982. The company changed its name to Pajero Manufacturing Co., Ltd. in July 1995.

Prev

Next

1968

Mitsubishi Heavy Industries, Ltd. completed the construction of the main building of Mitsubishi Kyoto Hospital.

1969

Mitsubishi Heavy Industries, Ltd. set up the division for its automobile business.

Mitsubishi Heavy Industries, Ltd. moved the division for its automobile business to Shiba, Minato City.

Launched the production of 4G3 model (Saturn Engine).

Launched the production of 4G3 model (Saturn Engine).

The 4G3 Saturn engines use Mitsubishi’s first overhead camshaft (OHC) mechanism for water-cooled in-line four cylinder gasoline engines, which were designed to yield high performance while controlling exhaust fumes that was becoming a social issue. This product line was named Saturn, following the precedents of the names “Venus” and “Mars” given to the aircraft engines manufactured during World War II.

The 1.3 liter 4G30 and 1.5 liter 4G31 models were installed in the first-generation Colt Galant launched in December 1969. The 1.6 liter 4G32 model was added in the following year. Galant GTO-MR was installed with a dual overhead camshaft (DOHC) engine for high output of 125 ps/6,800 rpm.

In 1973, when emission regulations were tightened, Mitsubishi was one step ahead of its competitors, having started producing engines that met the regulations since in 1972. These engines were of the 4G3 line. The engine variation expanded from the 2.0 liter 6G34 model with six cylinders for the Debonair as well as the 1.4 liter 4G33, 1.7 liter 4G35, and 1.8 liter 4G37 models, and were manufactured for decades.

- Years manufactured: 1969–1996

- Total production: 4,210,000

- Displacement: 1,300 cc–2,000 cc

- Models of cars equipped with these engines: Colt Galant, Galant GTO, Lancer, Debonair, Galant Σ

Prev

Next

Automotive research and development center was set up in Nagoya plant.

The soccer team of Mitsubishi Heavy Industries, Ltd. won the Japan Soccer League for the first time.

1970

Mitsubishi Motors Corporation was founded.

Mitsubishi Motors Corporation was founded.

Mitsubishi Heavy Industries, Ltd. advanced establishing a department dedicated to its automobile business in order to adapt to the age of fully internationalized automotive industries that were brought into reality by capital account liberalization. In February 1970, the company entered into a master agreement for a joint venture with Chrysler. With this agreement, Mitsubishi Heavy Industries transferred its automobile business department to the new venture. On April 22 of the same year, Mitsubishi Motors Corporation was established as a new company wholly owned by Mitsubishi Heavy Industries. Chrysler also began equity participation in this new venture in the form of a capital increase through third party allotment of new shares.

Moreover, with the business transfer agreement signed on the same day, the sales operations for the automobile business along with some of the plants owned by Mitsubishi Heavy Industries were transferred to Mitsubishi Motors as of midnight on June 1, 1970.

As soon as Mitsubishi Motors was launched, Mitsubishi vehicles were exported to North America and other regions through Chrysler’s sales network. In October of the same year, a US distributorship agreement (USDA) was executed with Chrysler, and then a Canada distributorship agreement with Chrysler Canada in December. In January of the following year, the Colt Galant, which Chrysler acclaimed, was launched as the Dodge Colt in the west coast of North America.

In May 1971, a small market distributorship agreement was signed with Chrysler International S. A. (CISA, based in London) to launch sales in markets other than North America through CISA.

Mitsubishi’s automobile business in overseas markets, which was one of the major objectives of the establishment of Mitsubishi Motors, started to off.

Prev

Next

Concluded an agreement with CMC to provide assistance on enhancing domestic production in Taiwan.

Concluded an agreement with CMC to provide assistance on enhancing domestic production in Taiwan.

Mitsubishi vehicles had already been exported to Taiwan since 1934. In October 1970, as its first overseas business operation project, Mitsubishi Motors oncluded an agreement with China Motor Corporation (CMC) in Taiwan to provide assistance on enhancing domestic production. The knock-down production of large trucks and the Delica trucks began in December 1973, and the makes of vehicles produced under the agreement gradually increased.

Since its group company Yulon Motor jointly manufactured mainly passenger cars with Nissan Motor Corporation, CMC only dealt with commercial vehicles by Mitsubishi. Yet in 1985, CMC launched the Minica called “Towny” with an 800-cc engine and released it as the first ever passenger car.

As CMC and Mitsubishi Motors worked closely together, Mitsubishi Motors and Mitsubishi Corporation began equity participation in CMC in 1986. CMC continues to manufacture and sell Mitsubishi vehicles in Taiwan today.

Prev

Next

100th anniversary of Mitsubishi Group.

1971

10 Minica Van EVs were delivered to Tokyo Electric Power Company.

10 Minica Van EVs were delivered to Tokyo Electric Power Company.

In October 1966, Tokyo Electric Power Company and Mitsubishi Heavy Industries, Ltd. entered into an agreement for entrusted research titled “Prototype and various tests of electric vehicles by improving existing batteries.” Mitsubishi Electric Corporation and Japan Storage Battery Co., Ltd. (currently GS Yuasa Corporation) also joined. The project explored potential electric vehicles (EV) based on the Minica Van, and in December 1969, the EV Minica Van (E12X model) was launched.

This EV had great accelerating power and climbing ability, demonstrating its capability that was as good as gasoline cars. It enjoyed a high reputation in a test-drive at Tokyo Electric Power Company’s Tokyo office.

The E12 model, an upgraded version of the E12X model, boasted the maximum speed of 80 km per hour and cruising distance of 70km (30km/h at constant speed). 10 E12 Minica Vans were delivered to Tokyo Electric Power as company cars.

Prev

Next

Launched the production of 4G4 model (Neptune Engine).

Launched the production of 4G4 model (Neptune Engine).

The 4G4 Neptune engines were water-cooled in-line four cylinder gasoline engines inheriting the OHV style. The 1.4 liter 4G41 model was installed in Galant FTO that was launched in November 1971. The 1.2 liter 4G42 model was later added for the Lancer, yet the production discontinued in 1981.

- Years manufactured: 1971–1981

- Total production: 520,000

- Displacement: 1,200 cc–1,400 cc

- Models equipped with these engines: Galant FTO, Lancer

Prev

Next

Entered into equity alliance with Chrysler.

Entered into equity alliance with Chrysler.

In February 1971, Chrysler requested Mitsubishi Heavy Industries, Ltd. to change method to equity participation based on the master agreement for a joint venture (executed in February 1970). In May of the same year, Mitsubishi Heavy Industries signed a second master agreement (an updated version of the first agreement), according to which the company switched over to equity investments in three stages from a one-time investment.

On the day this agreement was signed, Chrysler submitted the notice of acquiring shares in the new company (Mitsubishi Motors) to the Japanese government for approval. In September of the same year, Mitsubishi Motors, with the capital increased through third party allotment of new shares, issued 527,700 shares (face value of 10,000 yen) to start over as a motor vehicle company capitalized at 35.177 billion yen, with both Mitsubishi Heavy Industries holding 85 percent of the shares and Chrysler 15 percent.

The master agreement between Mitsubishi Heavy Industries and Chrysler continued for 14 years until it was terminated by the two companies in June 1985.

Prev

Next

1972

The soccer team of Mitsubishi Heavy Industries, Ltd. won the Emperor’s Cup JFA Japan Football Championship for the first time.

Kyoto Plant Rugby Team won the 24th Japan Company Rugby Football Championship for the first time.

Mitsubishi Rented Car Corporation (later Mitsubishi Auto Leasing Corporation) was founded.

Acquired shares in CPC of the Philippines.

Acquired shares in CPC of the Philippines.

Mitsubishi vehicles had been exported to the Philippines since 1955. Nissho Iwai Corporation (currently Sojitz Corporation) set up a distributor, and they began knock-down production afterwards.

After its establishment, Mitsubishi Motors joined Nissho Iwai and a local business in equity participation in Chrysler Philippines (CPC; Chrysler’s Philippine office) at the request of Chrysler and Chrysler International S.A. (CISA). They assembled and sold Colt Galant, Lancer, and Minica, among others at CPC.

When Chrysler completely withdrew its business from the Philippines, CPC’s name was changed to Canlubang Automototive Resources Corporation (CARCO), and the company was turned into a joint venture funded by Mitsubishi Motors, Nissho Iwai, and the local business.

In the 1980s, with the political instability that led to economic turmoil in the Philippines, demand for automobiles dipped. Consequently, in February 1987, following changes the Philippine government made to its automotive industry development plan in the same year, Mitsubishi Motors and Nissho Iwai jointly established a new company called Philippine Automotive Manufacturing Corporation (PAMOCR; located in Cainta, the Philippines).

Aiming to clarify, domestically and internationally, that the joint venture produced and sold Mitsubishi vehicles, PAMOCR was renamed to include “Mitsubishi” in its trade name. In August 1996, the company made a start as Mitsubishi Motors Philippines Corporation (MMPC), and it has served as our vehicle production and sales base to date.

Prev

Next

Kawasaki Baseball Team entered the 43rd Intercity Baseball Tournament and came second.

Launched the production of 4G5 model (Astron Engine).

Launched the production of 4G5 model (Astron Engine).

The 4G5 Astron engines were water-cooled in-line four cylinder gasoline engines, essentially the same as those of the 4G3 model, yet one size bigger being a 2-liter-class engine. In January 1973, the 2.0 liter 4G52 model was installed in the Galant GTO. The 1.8 liter 4G51 model was added to the lineup in May of the same year, the 2.4 liter 4G53 model in August 1974, and the 2.6 liter 4G54 model in June 1976. They were installed in Debonair, New Galant, Canter, and Rosa, among others.

In February 1975, Galant GTO with the 4G52 Astron 80 engine was launched. The engine of this four-cylinder model used a silent shaft system applied to the 4G52 engine, achieving quietness equivalent to an 8-cylinder. To pursue an ideal engine for the 1980s, we collectively named engines that used the silent shaft system as ’80 engines.

To meet the demand of the resource and energy conservation age, Mitsubishi Motors completed the development of the 2.4 liter 4D55 model in May 1980. This model is a diesel version of the 4G5 model to serve as Japan’s first diesel engine with a turbo designed for passenger cars, and it was installed in the Galant, and Eterna Σ and Λ. The 4D55 model was widely adopted for commercial vehicles afterwards, including Pajero and Delica. Then the 2.5 liter 4D56 model, Japan’s first engine with a turbocharger for passenger cars, was suited in May 1986, and in October 1988, a turbo version with an intercooler was added for the Pajero.

- Years manufactured: 1972–2013

- Total production: 5,220,000

- Displacement: 2,000 cc–2,600 cc

- Models equipped with these engines: Galant Σ, Debonair, Pajero

Prev

Next

1973

Founded ATC in the Philippines.

Founded ATC in the Philippines.

In 1971, following the Progressive Car Manufacturing Program (PCMP) issued by the Philippine government, aiming to increase the percentage of domestically produced cars and to acquire foreign currency, Mitsubishi Motors, Chrysler Philippines (CPC), and Nissho Iwai Corporation (currently Sojitsu Corporation) established the joint venture Asian Transmission Corporation (ATC; located in Canlubang, the Philippines) for parts manufacturing. In July of the same year, the construction of a plant began in Manila. The manufacturing of manual transmissions started in 1974, of engines in 1991, and of axles in 1995.

In 1998, with demand for these products growing in the Philippines and our export to the ASEAN member states and other Asian countries/regions increase, the production was relocated to a new plant built in an industrial park near the original plant in order to boost manufacturing capacity.

In June 2014, Mitsubishi Motors bought shares of ATC from Sojitsu and the manufacturing and sales company Mitsubishi Motors Philippines Corporation (MMPC) to hold 90 percent of shares in ATC, aiming to strengthen its production facility. Vehicle transmissions are manufactured by ATC in the Philippines.

Prev

Next

Founded MKM in Indonesia.

Founded MKM in Indonesia.

The export of Mitsubishi vehicles to Indonesia began in 1958. There were distributors and knock-down production bases for the Mitsubishi Jeep, Delica, and mid-sized trucks, yet it was an alliance with Mitsubishi Corporation and the local partner PT Krama Yudha (KY) that provided a foothold needed for the full launch of the company’s automobile business in Indonesia.

To adapt to the policy on domestic manufacturing in Indonesia, Mitsubishi Motors and Mitsubishi Corporation established PT Mitsubishi Krama Yudha Motors and Manufacturing (MKM) for the production of components for locally manufactured vehicles as a joint venture with KY in 1973. The production began in 1975.

The manufacturing of motor vehicles was outsourced to PT Krama Yudha Ratu Motors (KRM), which was wholly funded by KY and began the production of the Colt and mid-sized and large trucks in 1975. Later, Mitsubishi Motors, Mitsubishi Corporation, and KY established PT Mitsubishi Motors Krama Yudha Indonesia (MMKI; located in Bekasi, Indonesia) and began motor vehicle production in April 2017.

Furthermore, intending to restructure the marketing business, PT Krama Yudha Tiga Berlian Motors (KTB), which had sold Mitsubishi vehicles in Indonesia since 1973 under the distributorship agreement with Mitsubishi Motors, was split brands of Mitsubishi Motors and of Mitsubishi Fuso Truck and Bus Corporation. Then Mitsubishi Motors, Mitsubishi Corporation, and KY jointly established PT Mitsubishi Motors Krama Yudha Sales Indonesia (MMKSI; located in Jakarta, Indonesia) as a sales company exclusively for the Mitsubishi Motors brands in April 2017. In the Indonesian market, the Mitsubishi Motors brands’ vehicles are sold via MMKSI.

Prev

Next

Concluded an agreement to provide technical assistance for the 4G36 model engine to Hyundai Motor Company.

Acquired shares in SMC of Thailand.

1975

Established Meiko Motor Pool in Nagoya port in Aichi Prefecture.

1976

The “silent shaft” system won the Technological Development Award of the Society of Automotive Engineers of Japan, Inc.

The “silent shaft” system won the Technological Development Award of the Society of Automotive Engineers of Japan, Inc.

Most passenger cars used four-cylinder engines at the time. These engines were more resource- and energy-efficient and lower-cost than six- and eight-cylinder and rotary engines, whereas they were at a disadvantage in terms of the level of vibration and noise. It was already known at the time that vertical vibrations could be reduced by two balancer shafts counter-rotating at twice the speed of the crankshaft that were built in the cylinder block. Mitsubishi Motors strived to further control the level of vibration, and successfully developed the “silent shaft” system that dramatically reduced vibrations at low and high speed by placing the balancer shaft that rotated into the same direction as the crank shaft in a further upward position.

This silent shaft system made four-cylinder engines as quiet as eight-cylinder engines. It was installed in the 2 liter 4G52 Astron engine, and built in New Galant GTO as Astro 80 Engine.

In 1976, the silent shaft system won the Technological Development Award of the Society of Automotive Engineers of Japan, Inc.

The "Silent Shaft" system was also licensed to European manufacturers (Porsche, Volvo, Saab).

Prev

Next

Kyoto Plant Rugby Team won again in the 28th Japan Company Rugby Football Championship.

Began using the MM symbol for the front emblem.

Began using the MM symbol for the front emblem.

Mitsubishi Motors designed a new logo using the first letters of its name. Galant Σ that bore this “MM” symbol made its debut.

Since the motor vehicles Mitsubishi Motors manufactured and sold were designed to bond with users, the new symbol aimed to further highlight the unique images of Mitsubishi vehicles, each bearing the signature of Mitsubishi Motors.

The “mighty red” (left), our then-corporate color, represented sincerity and vitality, and the “lofty blue” (right) youth and fulfilling futures. The emblem was also used for public relations materials.

Mirage II and Lancer Fiore that were launched in February 1982 started using the new symbol “MMC” for the front emblem, followed by Tredia and Cordia launched the following month. This symbol was created to represent all Mitsubishi Motors vehicles.

In May 1992, taking into account a full upgrade to Galant and Eterna, the MMC logo used in ads and promotions, stores, and car bodies was replaced with the three-diamond logo.

Prev

Next

Introduced the MCA-JET system engine.

Introduced the MCA-JET system engine.

The Mitsubishi Clean Air-Jet Controlled Super Lean Combustion System (MCA-JET) was adopted for the engines of all Mitsubishi passenger cars, ranging from 500-cc engines (Minica 5) to 2.6-l engines (Debonair). MCA-JET delivered fuel efficiency and high performance, particularly in response to the age of resource and energy conservation. The engines with this pioneering MCA-JET met the 1978 motor vehicle emission control requirements, which were considered the world’s toughest at the time, before any other companies did.

MCA-JET, is short for Mitsubishi Clean Air-jet-controlled super lean combustion system, and has a jet valve, in addition to an intake/exhaust valve, in the combustion chamber. This empowers super lean air-fuel mixture or air to eject into a certain direction at the right time for the driving condition, enabling efficient combustion at the optimal air-fuel ratio. The MCA-JET system helped improve fuel efficiency and make exhaust gas cleaner.

Prev

Next

1977

Launched the production of 4G1 model (Orion Engine).

Launched the production of 4G1 model (Orion Engine).

The 4G1 Orion engines were small and lightweight engines (water-cooled in-line four cylinder gasoline engines) designed for greater efficiency with less displacement than the 4G3 engines to meet the demands of the energy conservation age after the oil crisis in 1973. The 1.3 liter 4G11 model was installed in Lancer in May 1977. This engine used the Mitsubishi Clean Air-Jet Controlled Super Lean Combustion System (MCA-JET), and it met Japan’s motor vehicle emission control requirements, which were considered the world’s toughest at the time, one year before they were enforced in 1978.

The 1.4 liter 4G12 model was installed in the Mirage launched in March 1978. With the full upgrade of the Mirage in October 1983, the 1.3 liter 4G13 and 1.5 liter 4G15 models with an enlarged bore were added.

In February 1982, the 4G12 model that used the modulated displacement technology was installed in Mirage II.

Furthermore, the 4G15 model with Mitsubishi Vertical Vortex (MVV) was installed in the new Mirage and Lancer that were launched in October 1991.

The 4G19 model installed in the new Colt that was launched in November 2002. The newly developed 1.3 liter DOHC MIVEC (with variable valve timing mechanism) engine combined with CVT (continuously variable transmission) delivered good engine response for a smooth ride. In its 10-15 mode, the engine accomplished the fuel efficiency of 20 km per liter (for a 1.3-liter car optionally equipped with the model), delivering the highest-level fuel efficiency for this vehicle class even in urban areas. Due to this performance, cars with this engine were certified as “super low-emission vehicles” that successfully cut 75 percent of exhaust fumes to meet the emission control requirements in 2000. The engine also met the 2010 fuel efficiency standards, and all cars equipped with this model became eligible for green tax breaks.

- Years manufactured: 1977–2014

- Total production: 9,680,000

- Displacement: 1,200 cc–1,600 cc

- Models equipped with these engines: Lancer, Mirage, Colt

Prev

Next

Hosted Mitsubishi Galant Tournament.

Hosted Mitsubishi Galant Tournament.

Mitsubishi Motors joined the sponsorship for the Dunlop Golf Tournament, a men’s professional competition that had been held since 1969, as the main organizer, and hosted the first Mitsubishi Galant Tournament at the Noto Country Club in 1977. This made Mitsubishi Motors Japan’s first automobile manufacturer that hosted a men’s professional golf tournament. Since its inauguration, the annual tournament gained in popularity as a circuit tournament that took players to highly challenging courses across Japan, from Hokkaido to Kyushu. Mitsubishi Motors’ products were presented as an extra prize for the winner and as a special award, which also contributed to the company’s publicity.

Starting from the 23rd competition in 1999, the tournament took on the new name “Field Mitsubishi Motors Tournament” to symbolize the support from the entire Mitsubishi Motors Group for further growth.

Mitsubishi Motors hosted the tournament until 2000 when it decide to complete overhaul of its advertising and promotional activities due to its tough financial condition at the time. The Mitsubishi Motors Group stepped down as the host in 2001, and the tournament was renamed “Mitsubishi Diamond Cup Golf” hosted by the Mitsubishi Group companies. In 2014, the tournament was renamed “Asia Pacific Open Diamond Cup Golf.”

Prev

Next

Founded Japan Automotive Engineering Co., Ltd.(currently Mitsubishi Automotive Engineering Co.,Ltd.)

Established Nagoya plant - Okazaki (currently Okazaki Plant - Okazaki).

Hosted the Mirage Bowl.

Hosted the Mirage Bowl.

As the preliminary advertising campaign for the new Mirage scheduled to be launched in March 1978, Mitsubishi Motors hosted the final game of the NCAA college football season, which enjoyed great popularity at the time, as the Mirage Bowl at Korakuen Stadium to kindle target users’ interest and enhance its public image.

The game demonstrated the authentic speed and power of a football game, along with the music played by the colleges’ marching bands and cheerleaders’ spectacular performance. The event attracted 90,000 spectators to the pre-game events and the game combined. The game that was broadcast live on TV served as the introduction of authentic football to the Japanese public.

The Mirage Bowl moved to the Japan National Stadium in 1979 and continued to enjoy a full stadium crowd every year. In 1985, after the ninth Mirage Bowl, Mitsubishi Motors decided that it had accomplished its intended goals and ceded the initiative as the host.

Prev

Next

1978

Created 2 channels of domestic distributors.

Created 2 channels of domestic distributors.

Mitsubishi Motors established Car Plaza to enhance its market (108 dealers and 186 sales offices at the time). Car Plaza dealers all opened on March 1, 1978, the day Mirage was launched. Following the establishment of Car Plaza, the company’s existing passenger car dealerships were renamed Galant Shops.

In January 2003, as part of the company’s passenger car marketing business reform in Japan, the sales systems in the two channels of Galant Shops and Car Plaza dealers were integrated into the new, full-line sales network “Mitsubishi Motors” that would deal in all lines of passenger cars. The company also gave its dealerships a makeover by adding its new corporate identity (CI) design to the interior and exterior of Mitsubishi dealers in an effort to improve customer satisfaction and its brand image. The dealers desplayed refurbished signage mostly in red and silver (the corporate colors at the time) and used simple interior designs to accentuate the beauty of the cars.

In 2016 the new brand message “Drive Your Ambition” was unveiled, and 5,000 dealers around the world took up a new design for their shops’ interior and exterior to enhance the brand image. The new design at these dealers features the basic color scheme of black, white, and gray, with dynamic red lines as accents.

Prev

Next

1979

The soccer team of Mitsubishi Heavy Industries, Ltd. won three titles for the first time ever.

Acquired shares in CAL of Australia.

Acquired shares in CAL of Australia.

The export of Mitsubishi vehicles to Australia began in 1957. Once it was founded, Mitsubishi Motors entered into a distributorship, trademark, and technical assistance agreement with Chrysler Australia Ltd. (CAL), which was Chrysler’s manufacturing base in Australia, as Mitsubishi and Chrysler had an equity alliance at the time. In 1971, it launched the knock-down production of the Colt Galant.

In April 1979, Mitsubishi Motors complied with a request from Chrysler to acquire shares in CAL, which had begun to scale down its international business. Mitsubishi Motors and Mitsubishi Corporation set up a joint venture to buy out CAL. In October 1980, CAL was renamed Mitsubishi Motors Australia Ltd. (MMAL; located in Adelaide). After the acquisition, Mitsubishi Motors gradually increased its ownership ratio, and eventually acquired full ownership of MMAL.

In 1985, MMAL increased the width of Galant Σ (Sigma) by 65 mm to develop a vehicle designed specifically for consumers in Australia. This product was launched as Magna with a 2.6-liter engine. MMAL also developed a station wagon based on Magna to add to the line.

In 1988, Mitsubishi Motors imported and sold the Magna station wagons at dealerships in Japan.

In 2005, MMAL developed the first new motor vehicle in nine years as Mitsubishi Motors’ manufacturer and distributor in Australia. The vehicle was a high-class sporty sedan named 380, which was launched onto the market as the last Mitsubishi vehicle manufactured in the country. Since the end of the local production in March 2008, MMAL has served as a Mitsubishi sales company to date.

Prev

Next

Established Gamagori Motor Pool in Gamagori port in Aichi Prefecture.

Launched the production of 4G6 model (Sirius Engine).

Launched the production of 4G6 model (Sirius Engine).

The 4G6 Sirius engines were developed to serve as water-cooled in-line four cylinder gasoline engines with displacement that filled the gap between the 4G3 and 4G5 engines. The 1.8 liter 4G62 model was installed in Lancer EX launched in February 1980. The 4G6 model aimed to gain internationally competitive advantages as a small, lightweight, low-cost, and high-performance engine. It was 20 kg lighter and 65 mm shorter than the 4G5 model. The 2.0 liter 4G63 model was added in April of the same year, and it became Mitsubishi Motors’ flagship passenger car engine.

This 4G6 engine was the first engine produced at the Shiga Plant that had been built in 1979.

In June 1984, the 4G63 Sirius DASH (dual action super head) engine was installed in the Galant Σ and Starion. This high-power energy-efficient engine was the first to achieve 200 horsepower for the front-wheel drive vehicles.

With the full upgrade of the Mirage and Galant for the launch in October 1987, the 1.6 liter 4G61 model was added. The Galant VR-4 launched in December of the same year was equipped with a 4G63 DOHC turbo engine with an intercooler, which delivered power as high as 205 ps/6,000 rpm. In April 1989, the 1.8 liter 4G67 model was added. In August of the same year, the 2.4 liter 4G64 model was installed in the Delica and other vehicles.

The 4G6 engine was then developed into the 1.8 liter 4D65 diesel model for passenger cars that were meant to follow the 4D5 engine. This model was installed in the Mirage and Lancer Fiore launched in December 1983. A turbocharged version of this model with an intercooler was adopted for Galant Σ in February 1984, and the 2.0 liter 4D68 model was added in May 1992.

The 4G69 model was installed in the new Grandis that was launched in March 2003. The newly developed 2.4 liter MIVEC (variable valve timing and lift mechanism) engine combined with INVECS-II4A/T delivered good engine response for smooth performance.

The production of the 4G6 Sirius engines lasted more than 30 years, which was longer than that of the 4G3 Saturn engines.

- Years manufactured: 1979–2016

- Total production: 6,360,000

- Displacement: 1,600 cc–2,400 cc

- Models equipped with these engines: Galant, Delica, Lancer EX, Mirage

Prev

Next

Established Kyoto Plant - Shiga.

1981

Offered the “silent shaft” technology to Porsche.

Established Mitsubishi Motor Sales of America, Inc. (MMSA) in the US.

Established Mitsubishi Motor Sales of America, Inc. (MMSA) in the US.

The export of Mitsubishi vehicles to the United States had initiated with the export of scooters in the 1950s. With the signing of the US distributorship agreement (USDA) with Chrysler in October 1970, the Dodge Colt (Colt Galant in Japan) vehicles were shipped out the same month as the first four-wheelers exported to the United States.

Chrysler had the exclusive right to distribute Mitsubishi vehicles in the United States under the USDA at the time. In 1982, Mitsubishi Motors established Mitsubishi Motor Sales of America, Inc. (MMSA; located in Fountain Valley, California) as its wholly owned distributorship. Mitsubishi Corporation also acquired shares in MMSA the following year, and then started sales of the small pickup truck Forte.

In January 2003, MMSA merged with the manufacturing company Mitsubishi Motor Manufacturing of America, Inc. (MMMA) to make a start as Mitsubishi Motors North America Inc. (MMNA; located in Cypress, California) to manage sales, production, finance, and R&D in North America.

MMNA discontinued its manufacturing business in November 2015. It has served as a Mitsubishi vehicle sales company in the United States to date.

Prev

Next

1982

Introduced the variable displacement engine “MD”.

Introduced the variable displacement engine “MD”.

Modulated displacement (MD) is an engine technology that allows the vehicle to automatically run on two or four cylinders according to how it is driven. The engine basically is a 1.4-liter four-cylinder engine, but uses computer control to close the intake and exhaust valves for two cylinders, so that the vehicle runs on two cylinders when it sits idle, decelerates, runs at a constant speed of up to around 70 km per hour (in 4th gear), or in other low-load condition. During acceleration and high-speed driving and other high-load conditions, it runs on four cylinders. This MD technology dramatically improved fuel efficiency (20 km per liter in its 10 mode).

This MD engine, which is a type of cylinder deactivation engine, was installed in the Mirage in the same month.

Prev

Next

Began using the MMC symbol for the front emblem.

Acquired shares in Hyundai Motor Company of South Korea.

1983

Established PROTON in Malaysia.

Established PROTON in Malaysia.

Perusahaan Otomobil Nasional Sdn. Bhd. (PROTON; located in Shah Alam, Malaysia) was founded as a joint venture by Mitsubishi Motors, Mitsubishi Corporation, and Heavy Industries Corporation of Malaysia Bhd. (HICOM), under then-Malaysian Prime Minister Mahathir Mohamad, who envisioned establishing a national car company.

With support provided by Mitsubishi Motors and Mitsubishi Corporation, the production of Saga as Malaysia’s first national car, which was based on Mitsubishi Motors’ Lancer Fiore, began in 1985. In 2000, PROTON launched Waja, its first independently developed vehicle. In February 2004, the company launched GEN-2 equipped with its independently developed engine, demonstrating its technological competence that only became greater each year and gaining public support as the symbol of Malaysia’s industrialization.

As PROTON reached an advanced technical level, Mitsubishi Motors sold all shares it held in the Malaysian company to terminate the equity alliance in 2004.

In March 2005, Mitsubishi Corporation and Edaran Otomobil Nasional Berhad (ECO), which was a PROTON dealer, jointly established Mitsubishi Motors Malaysia Sdh. Bhd. (MMM), and Mitsubishi Motors entered into a distributorship and service agreement with MMM the following month. Mitsubishi vehicles are sold in the Malaysian market via MMM.

The cooperative ties between Mitsubishi Motors and PROTON continued after the termination of the equity alliance, through licensing of technologies for components as well as engine and transmission trading. In February 2006, the two companies signed a memorandum for a new alliance to collaborate in development and production. In December 2008, Mitsubishi Motors entered into an agreement with PROTON for development and production of a new motor vehicle.

Prev

Next

1984

Established Ralliart, Inc.

Established Ralliart, Inc.

As motorsport enjoyed a growing number of fans, Ralliart, Inc. was established to meet the diversified needs of car users and foster sound awareness of motorsport. Its objectives were to provide a range of excellent services for motorsport lovers in Japan and overseas, develop motorsport parts and gear, and establish a solid distribution system for those products.

The major part of Ralliart’s business consisted of the activities shown below. In addition to the motorsport business, the company ran side projects to raise awareness of road traffic safety, such as organizing driving lessons for women.

(1) Getting involved in various motorsport events in Japan and overseas

(2) Planning and managing a range of services for motorsport fans, training sessions for people who sought to obtain a license, and auto racing workshops

(3) Developing and marketing motorsport parts and gear

(4) Developing and marketing a range of character (Ralliart) goods

Since its establishment, Ralliart had the privilege of enjoying support from numerous customers while it engaged in activities for motorsport. However, Ralliart scaled down its operations at the end of March 2010 after Mitsubishi Motors announced its team’s hiatus from the WRC (FIA World Rally Championship) in December 2005, and the discontinuation of its team’s activities in the Dakar Rally in February 2009. With the downsizing, Ralliart discontinued the operation and management of the overall activities for user support in motorsport excluding the sales of Ralliart goods.

Prev

Next

Integrated Mitsubishi Motor Sales Company.

Integrated Mitsubishi Motor Sales Company.

With the domestic and international business environment growing tougher owing to the second oil crisis in 1979, Mitsubishi Motors and Mitsubishi Motor Sales Company (“Mitsubishi Motor Sales”) entered into a business transfer agreement on May 28, 1984, as a step toward integration. The agreement was to enable the two companies to quickly respond to changes in the business environment surrounding Mitsubishi Motors and to user trends, and to pursue development and marketing based on accurate knowledge of market needs. This integration did not take the form of a merger. Instead, Mitsubishi Motor Sales transferred its business in Japan to Mitsubishi Motors. Following this business transfer, all employees of Mitsubishi Motor Sales who were on the payroll on the transfer date also became Mitsubishi Motors employees.

The integration of Mitsubishi Motors and Mitsubishi Motor Sales marked the end of the history of separation between engineering and marketing at Mitsubishi Motors, which had continued since the establishment of Fuso Motors Sales Co., Ltd. in December 1949.

Prev

Next

1985

Electronically Controlled Suspension (ECS) won the Technological Development Award of the Society of Automotive Engineers of Japan, Inc.

Electronically Controlled Suspension (ECS) won the Technological Development Award of the Society of Automotive Engineers of Japan, Inc.

Electronic control suspension (ECS) was designed to automatically control a vehicle’s suspension characteristics (the spring constant and shock absorbers’ damping force) to keep them in the optimum state in changing driving conditions, thereby delivering a comfortable ride and controllability. ECS also had the function of keeping stable the vehicle height, in order to adjust to changes in the weight of loads/passengers, speed, and road conditions, along with the extra high ride height function that increased the ride height by 40 mm while the vehicle was parked.

Prev

Next

Established the brand message: Ii-machi, Ii-hito, Ii-kuruma (“Great Town, Great People, Great Cars”)

Established DSM (later Mitsubishi Motor Manufacturing of America Inc., or MMMA) in the US.

Established DSM (later Mitsubishi Motor Manufacturing of America Inc., or MMMA) in the US.

In 1981, voluntary export restraints were imposed on the export of automobiles to the United States. While the restraints continued, Mitsubishi Motors decided to launch local production. In 1985, the company established Diamond Star Motors Corporation (DSM; located in Normal, Illinois) jointly with Chrysler, with which it had an equity alliance at the time.

In 1988, a new plant was built in Illinois to launch the production of the Eclipse and In1990, they were imported to be sold via sales companies in Japan.

In October 1991, Mitsubishi Motors bought all shares Chrysler held in DSM and, in July 1995, it changed the name of DSM to Mitsubishi Motor Manufacturing of America, Inc. (MMMA; located in Normal, Illinois).

In January 2003, MMMA merged with the local sales company Mitsubishi Motor Sales of America, Inc. (MMSA) to make a start as Mitsubishi Motors North America Inc. (MMNA; located in Cypress, California) to manage sales, production, finance, and R&D in North America.

Production by MMNA surpassed 220,000 in 2000. However, in the wake of the termination of manufacturing as an OEM for Chrysler and the collapse of Lehman Brothers, production dipped dramatically to 20,000 in 2009.

MMNA began the production of the Outlander Sport (RVR in Japan) in 2012 to improve production efficiency and raise the production and capacity utilization rate, which was geared toward not only the North American markets, but Russia, the Middle East, and Latin America.

However, exports to Russia, which had made up 30 percent of the company’s production, dropped dramatically in late 2014. The manufacturing of vehicles by MMNA had to be transferred to the Okazaki Plant because of this significant decrease, and at the end of November 2015, the manufacturing business in the United States was discontinued.

Prev

Next

Launched the production of 6G7 model engine.

Launched the production of 6G7 model engine.

The 6G7 engines were the first V-type six-cylinder gasoline engines developed for Mitsubishi Motors’ passenger cars. The 2.0 liter 6G71 and 3.0 liter 6G72 models were installed in the fully restyled Debonair V in August 1986.

In May 1990, the 2.5 liter 6G73 model installed in Diamante served as a pioneer of the 2.5 liter engine market.

In October 1992, the 3.5 liter 6G74 model was installed in Debonair, and later in Pajero.

The 3.8 liter 6G75 model was installed in Endeavor, the SUV launched exclusively onto the North American market in 2003. In Japan, it was installed in Super Exceed, the highest-grade Pajero, in November 2005. The engine was designed to deliver a quieter and smoother ride with a premium feel. Although its maximum power of 219 ps and maximum torque of 34.3 kg-m were almost the same as the conventional 6G74 model, they met the 2005 exhaust emission standards.

- Years manufactured: 1985 - present

- Total production: 8,080,000 (at the end of 2018)

- Displacement: 2,000 cc - 3,800 cc

- Models equipped with these engines: Debonair V, Pajero, Diamante, Debonair

Prev

Next

1986

Acquired shares in CMC of Taiwan.

1987

Established PAMCOR (currently MMPC) in the Philippines.

Electronically controlled power steering “EPS” won the Technological Development Award of the Society of Automotive Engineers of Japan, Inc.

Electronically controlled power steering “EPS” won the Technological Development Award of the Society of Automotive Engineers of Japan, Inc.

Electronic Power Steering (EPS) achieved a much-awaited significantly lighter feel to maneuvers for parking than conventional power steering. Its straight-running stability delivered a smooth ride at low speed, and an optimal and improved steering feel for a ride at high and medium speed.

EPS was adopted for Galant Σ and Eterna Σ that were launched in 1983.

Prev

Next

Established Suiryo Service Co., Ltd.

Introduced active electronically controlled suspension, “Active ECS”.

Introduced active electronically controlled suspension, “Active ECS”.

Active ECS (Active Electronic Control Suspension) electronically controls the internal pressure of the shock absorbers and air springs installed in the front and rear suspensions independently on all four wheels, enabling the vehicle to maintain its body posture nearly parallel to the road surface even when driving conditions change due to road surface conditions.

This Active ECS is designed to control the inner pressure of the air springs, in addition to ECS’s functions to switch between running soft and hard and to control the car height that were already used for Mitsubishi vehicles on the market. Controlling the inner pressure minimizes car body roll during cornering; the lift/dip of the front/rear of the car when the vehicle is started, accelerated, or brake; and bouncing up and down when the vehicle runs over bumps. This was developed as the world’s first active control on the leveling of chassis height added to the ECS technology, delivering smooth handling, and a comfortable steady ride, coupled with greater starting ability and braking stability. Active ECS was used for the Galant that was launched the same year.

In 1988, this technology won the Technological Development Award of the Society of Automotive Engineers of Japan, Inc.

Prev

Next

Mizushima plant achieved production of a cumulative total of 10 million units.

1988

Established property management companies at each plamts.

Established Mitsubishi Auto Credit-Lease Corporation.

Offered the “silent shaft” technology to Volvo.

Shares listed on First Section of stock exchanges.

1989

Established Mitsubishi Motors Europe B.V. (MME) in the Netherlands.

Established Mitsubishi Motors Europe B.V. (MME) in the Netherlands.

The export of Mitsubishi vehicles to Europe began in 1956. In 1971, the year Mitsubishi Motors was established, Chrysler had the exclusive right to distribute Mitsubishi vehicles in Europe under the distributorship agreement signed between the two companies in an equity alliance.

In 1974, Chrysler agreed that Mitsubishi Motors would launch business activities on its own in the region. In August of the same year, Mitsubishi Motors became the first Japanese automobile distributor in Europe when it entered into a full-line dealership agreement with a local enterprise to sell its vehicles in Belgium and Luxembourg. Following the agreement, the company started sales of Galant and Lancer.

In 1977, Mitsubishi Motors opened Liaison Office Europe (LOE; located in Rotterdam, the Netherlands) or “Europe Office” as known in Japan, as its representative office for information gathering and research. The company also established MMC Truck Parts Europe B.V. (MTP; located in an eastern suburb of Schiphol, the Netherlands) as a component storage depot it wholly owned to ensure the supply of spare parts for Mitsubishi vehicles exported to Europe. In January 1989, MTP was renamed Mitsubishi Motors Europe B.V. (MME; located in Amsterdam, the Netherlands).

In April of the same year, MME took on the responsibility to oversee Mitsubishi Motors’ overall business in Europe, including business operation needed to be a certified enterprise, technical studies and research.

In April 1993, Mitsubishi Motors established Mitsubishi Motors R&D Europe GmbH (MRDE in Trebur, Germany) responsible for design, tests, and authorization to further enhance its marketing and distribution in Europe, and Mitsubishi Motors Sales Europe B.V. (MMSE in Amsterdam, the Netherlands) for marketing and selling vehicles and components in close conjunction with distributors across Europe, along with a range of services.

In December 2002, MMSE, as a full-line sales company, was integrated into MME to form the business that oversees Mitsubishi Motors’ business in Europe. The objective of this integration was to ensure greater consistency in the business in this region that encompasses the sales and marketing of products, parts, and goods, as well as the supervision of distribution and the production business.

Today, MME oversees Mitsubishi Motors’ business in Europe, and MRDE conducts motor vehicle-related research, tests, and studies.

Prev

Next

Offered the “silent shaft” technology to SAAB.

Introduced a flexible hours schedule called “flex time”.

Conducted the first ever capital increase through public stock offering since being listed.

Conducted the first ever capital increase through public stock offering since being listed.

In December 1988, Mitsubishi Motors listed its stock shares on the first sections of the Tokyo, Osaka, and Nagoya Stock Exchanges. One year later, the company conducted its first public offering to raise additional capital (1,110 yen per share, 80 million shares in total). Out of the total of 88.8 billion yen that was raised, 44.4 billion yen was capitalized. The company’s capital after this public offering added up to 109.47745 billion yen (853.89 million shares issued in total).

▶ Click here to visit the corporate profile page

Prev

Next

1990

Introduced traction control system “TCL”.

Introduced traction control system “TCL”.

The Traction Control System (TCL) is designed to prevent the vehicle from skidding out of the lane due to excessive acceleration when cornering. The TCL is an ideal driving force control device equipped with the trace control and slip control functions. The trace control function, the world’s first technology, makes full use of a computer to detect how the car is driven based on the speed and steering angles, so that the engine output is automatically and optimally controlled to prevent excessive lateral acceleration. The slip control function is to avert the vehicle from slipping when it is started and accelerated on a slippery road surface, such as a snow-covered road.

In 1991, this technology won the Technological Development Award of the Society of Automotive Engineers of Japan, Inc.

Prev

Next

Introduced Mitsubishi intelligent cockpit system “MICS”.

Introduced Mitsubishi intelligent cockpit system “MICS”.

The Mitsubishi Intelligent Cockpit System (MICS) is designed to adjust the positions and angles of the seat, rearview mirror, side view mirror, and steering wheel all at once. It also has the functions to identify people, deduce the position suitable for each physique based on ergonomics data, and judge conditions for easy getting in and out of the car, so that adjustments are quickly made to keep the driver’s seat and the space around it easy-to-use. These functions make it easy for drivers to obtain a safe and comfortable driving environment.

Prev

Next

The soccer team of Mitsubishi Motors Corporation (later Urawa Red Diamonds) launched its activities.

Changed the name of Shinryo Automotive Service Co., Ltd. to Mitsubishi Automotive Techno-Service Co., Ltd.

1991

Launched the production of 4G9 model engine.

Launched the production of 4G9 model engine.

The 4G9 engines were developed as a new line of in-line four cylinder gasoline engines. They were the products of the thorough pursuit of highly efficient, small and lightweight engines. In June 1991, the 1.8 liter 4G93 model was installed in RVR. Following this, the new Mirage and Lancer launched in October of the same year were equipped with the 1.5 liter 4G91 model and the 1.6 liter 4G92 model.

In October 1992, the Mitsubishi Innovative Valve Timing and Electronic Control system (MIVEC) was built in the Mirage and Lancer. MIVEC was a 4G92 DOHC that delivered the high performance of 110 ps and the fuel efficiency of 16.0 km per liter in the 10-15 mode.

In October 1993, the MVV system was adopted for the 4G93 SOHC to be installed in the Galant and Eterna.

The 2.0 liter 4G94 GDI engine was installed in Pajero iO that was launched in June 2000. Acceleration performance was improved, and in 2010, it met the new fuel efficiency standards (2WD vehicles with three doors excluded) and conformed to the 2000 vehicle emission control requirements (applied to all vehicles).

- Years manufactured: 1991–2014

- Total production: 2,450,000

- Displacement: 1,500 cc–2,000 cc

- Models equipped with these engines: Lancer, Mirage, Galant, Pajero iO, Lancer Cedia

Prev

Next

Introduced the Caregiver Leave System.

Launched the production of 6A1 model engine.

Launched the production of 6A1 model engine.

6A1 series engine series was developed as the successor to the 6G7 series V6 engines. The 1.6 liter 6A10 model was the world’s smallest V6 engine installed in the Mirage that was launched in January 1992. 1.8 liter 6A11 and 2.0 liter 6A12 were installed on Galant and Eterna that were launched in May 1992. What is notable about the 6A12 model is that it was the first engine of this class that used a twin-turbocharger and an intercooler.

The Galant and Legnum that were launched in August 1996 adopted the 6A13 model, which used a 2.5 liter V6 DOHC twin-turbo intercooler with the maximum output of 280 ps and the maximum torque of 37.0 kg-m. This engine was installed in VR-4 and delivered a powerful ride, with its highest-level power in the class, delivered a powerful ride.

- Years manufactured: 1991–2007

- Total production: 320,000

- Displacement: 1,600 cc–2,500 cc

- Models equipped with these engines: Lancer, Mirage, Galant, Diamante

Prev

Next

Issued unsecured bonds with warrants.

Changed the name of Daiya Automotive Transportation Co., Ltd. to Mitsubishi Automotive Logistics Co., Ltd.

Hosted Star Camp.

Hosted Star Camp.

Mitsubishi Motors hosted the Star Camp across Japan, with the support of the local government of the venue. The objective of the event was to promote activities in close contact with nature through car camping so that participants would learn the importance of the natural environment. As one of the country’s biggest camping events, the Star Camp enjoyed 1,000 groups of participants every year from 1991 to 1997.

In 2007, it was held for the first time in ten years and continued until 2015 as an annual event in Asagiri Kogen, Shizuoka, for fans of automobile tourism and camping across Japan.

Since 2017, the Star Camp has been held in more than one venue, offering activities designed for a wide range of participants to enjoy the outdoors. These activities include family programs designed so that for both adults and small children can enjoy and programs to provide hands-on lessons to acquire know-how that can be useful outdoors. There were also test drives to experience the performance of a Mitsubishi sports utility vehicle (SUV) or 4WD, and a movie played using electricity stored in the vehicle provided by the power supply function of Outlander PHEV.

Prev

Next

Introduced vertical vortex lean-burn engine, “MVV”.

Introduced vertical vortex lean-burn engine, “MVV”.

The Mitsubishi Vertical Vortex (MVV) engine was released featuring the formation of two large vertical vortices, an "air-only vertical vortex" and a "mixture (air and gasoline) vertical vortex," in the intake air flow drawn into the cylinder through the ingenious shape of the intake port and other means. The movements of these vortexes coupled with the design of the most suitably shaped combustion chamber enables stable combustion even when the mixture inside the cylinders is extremely lean, with the air-fuel ratio of up to around 1:25, far exceeding the theoretical air fuel ratio which is about 1:14.7 in the case of gasoline.

It is difficult to stabilize combustion if the air is leaner than the theoretical air-fuel ratio. Hence, Mitsubishi Motors worked on research and development in multiple fields and, consequently, created the engine with cleaner emissions that made driving easier and improved fuel efficiency by applying the world’s first vertical vortex technology.

Mitsubishi Motors also adopted the all-range air fuel ratio sensor designed to measure the air-fuel ratio in all operating ranges. With this sensor, the engine’s fuel efficiency was up a little more than 20 percent (in the 10 mode), while the output and ease of driving were almost the same as conventional engines.

In 1992, this technology won the Technological Development Award of the Society of Automotive Engineers of Japan, Inc.

Prev

Next

Established Netherlands Car in the Netherlands.

Established Netherlands Car in the Netherlands.

In August 1991, Mitsubishi Motors acquired shares in Volvo Car B.V., a joint venture established to manufacture passenger cars in the Netherlands under the agreement for a joint passenger car business signed between the Dutch government and Volvo.

In December of the same year, the business was renamed Netherlands Car B.V. (NedCar; located in Limburg, the Netherlands). Mitsubishi Motors became the first Japanese automobile manufacturer that launched local production in the heart of Europe.

In May 1995, NedCar began the production of the five-door hatchback Carisma, which Mitsubishi Motors had developed for the European market. In October the following year, four-door Carisma sedans (with a right-hand steering wheel) made by NedCar were exported to Japan for sale.

After the Dutch government withdrew from this joint venture in 1999, and Volvo in 2001, NedCar became Mitsubishi Motor’s wholly owned subsidiary.

However, Mitsubishi Motors reviewed its production network around the world in the context of the dramatically changing environment surrounding the automotive business. As a result of this review, the company entered into a master agreement with VDL Groep B.V. (VDL; located in Eindhoven, the Netherlands) for the transfer of all shares it held in NedCar on July 11, 2012. On December 14, Mitsubishi Motors completed the transfer to VD Leegte Beheer B.V. (VDL’s wholly owned subsidiary), which marked the end of its vehicle manufacturing at NedCar as its production base in Europe.

Prev

Next

1992

Introduced Senior Reemployment System (Senior System).

Introduced active safety system “INVECS”.

Introduced active safety system “INVECS”.

The Intelligent & Innovative Vehicle Electronic Control System (INVECS) was the world’s first technology designed to recognize and judge changes in where the vehicle ran on behalf of the driver and rightly control the car as the driver would intend to (fuzzy control). The system consists of six functions, namely the fuzzy shift 4AT, fuzzy TCL, electronically controlled full-time 4WD, active 4WS, active preview ECS, and air purifier for fuzzy air conditioning. In 1993, this technology won the Technological Development Award of the Society of Automotive Engineers of Japan, Inc.

1. Fuzzy shift 4AT

This function is to recognize the degree of each slope/curve to control the engine output.

2. Fuzzy TCL

In addition to the conventional TCL (Traction Control System), a function that recognizes flat roads, uphill and downhill, and controls and regulates engine output.

3. Electronically controlled full-time 4WD

This full-time 4WD electronically controls the distribution of driving force applied to the four wheels in line with the road and driving conditions. The ratio of driving force distributed to the front and rear wheels is basically 32:68, and to the rear wheels and right/left wheels 50:50. This was also the world’s first technology that combined 4WD and TCL.

4. Active 4WD

The front and rear wheels are steered into the same direction (coordinated control) to keep the vehicle body level over the road when the car switches lanes at high speed. This function is to automatically adjust instantaneous reversed control in the low- to mid-speed range and the rear wheel steering angle in line with the road condition, to this conventional coordinated control to keep the vehicle even more stable.

5. Active preview RCS

In addition to the conventional active electronically controlled suspension "Active ECS," the system detects the road surface conditions in front of the vehicle using ultrasonic waves and recognizes road gradients to control vehicle stability.

6. Air purifier for fuzzy air conditioning

This function is to apply fuzzy control to the overall temperature and humidity using an air purifier.

Prev

Next

Introduced variable valve timing engine “MIVEC”.

Introduced variable valve timing engine “MIVEC”.

The Mitsubishi Innovative Valve Timing and Lift Electronic Control System (MIVEC) is an engine equipped with the variable valve timing and displacement technology. It is designed to automatically switch between its three modes according to where and how the vehicle runs. These modes are the high-speed mode when the car is going fast; the low-speed mode when the car starts, acclerates, and/or ascends a slope; and the MD (variable displacement) mode when it runs in an urban area. The innovative variable valve timing technology delivers high output, low fuel consumption, and clean performance, thereby enabling highly efficient driving ideal for drivers. MIVEC was first used for the Mirage in 1992. Improvements were continuously made to it thereafter for greater performance. A mechanism that continuously optimally controls intake and exhaust valve timing was adopted in the Outlander launched in 2005, the Delica D:5 launched in 2007, and the Galant Fortis. This system, which constantly varied the cams on the intake side and exhaust side separately, enables more precise control based on the engine speed and load than a system designed to control only the intake side, achieving high output, low fuel consumption, and clean performance at a high level.

The new MIVEC engine is designed for constant variable control of intake valve timing and valve lift volume with its simply structured SOHC. It was adopted for the RVR, Galant Fortis, Galant Fortis Sportback, and Delica D:5 that were launched in 2011, and for the Outlander launched in 2012.

Prev

Next

Launched the production of 4M4 model diesel engine.

Launched the production of 4M4 model diesel engine.

The 4M4 series engine series was developed to achieve both high output and low emissions for passenger car diesel engines. In July 1993, the 2.8 liter 4M40 turbo engine with an intercooler was installed in the Pajero. This engine made the vehicle considerably easier to drive, achieving the greatest torque in this class (30 kg-m/rpm). In 1992, it met the diesel vehicle emission control requirements. Moreover, various measures were taken to reduce vibrations and noise.

In September 1999, the Pajero was fully restyled for the first time in eight and a half years. It was equipped with the 3.2 liter 4M41, which is an in-line 4-cylinder diesel engine with 4-valves per cylinder, a DOHC valvetrain, and intercooler-turbocharger. This newly developed engine of the new generation was an evolved diesel engine designed to achieve high output, high torque, and low fuel consumption. It boasted the output of up to 175 ps and the torque of up to 39 kg-m/rpm, which were the highest power in the class and increased fuel efficiency by 27 percent compared to conventional engines. In 2005, it met the fuel efficiency standards for diesel vehicles. With the adoption of new technologies for injection pumps, catalyst, the engine also met long-term emission control requirements.

- Years manufactured: 1992–2018

- Total production: 1,010,000

- Displacement: 2,800 cc–3,200 cc

- Models equipped with these engines: Pajero, Mitsubishi Jeep

Prev

Next

1993

Established the brand message: Creating Together.

Developed Libero electric vehicle in collaboration with Tokyo Electric Power Company.

Developed Libero electric vehicle in collaboration with Tokyo Electric Power Company.

Mitsubishi Motors developed the Libero electric vehicle (Libero EV) in collaboration with Tokyo Electric Power Company, and sold 36 to government agencies and major corporations.

Libero EV was developed by replacing parts of Libero Cargo with those of electric vehicles. Based on the results of an assessment of Lancer Van EV, Libero EV was equipped with lead batteries, a motor, and a transmission designed specifically for the vehicle. In addition, it had greater suspension and braking, low rolling resistance tires, an electric heat pump for air conditioning, electric power assisted steering, and other technologies for high efficiency, thereby achieving the mileage of 165 km with a single charge (at the constant speed of 40 km per hour) and the acceleration performance of 4.1 seconds for 0-40 km per hour (maximum speed of 130 km per hour). The manufacturer's suggested retail price was 11.23 million yen.

Prev

Next

Established Mitsubishi Motor Sales Europe B.V. (MMSE) in the Netherlands.

Set up Automobile Information Service for Children.

Set up Automobile Information Service for Children.

In 1992, the social studies textbook for fifth graders highlighted that the automotive industry was Japan’s iconic key industry, in place of the steel industry that had always been listed as one. Following this, information requests from elementary school teachers and children were in surge, as did requests for our corporate profile and a wide range of queries and consultations.

In response to this growing interest, Mitsubishi Motors made internal arrangements to open an Automobile Information Service for Children to answer more questions actively and meet their requests.

Mitsubishi Motors was the only company in the automotive industry that launched this unique initiative of offering information services for school children. It runs from late July to early December each year to receive and answer a variety of questions about the automotive industry in general by phone (toll-free) and by mail. We have also offered an email information services for elementary school children since 2009.

Web page designed as a learning tool for children is always available, which illustrates the process from product development to sales and presents animations and videos showing how cars are produced at a plant. Furthermore, the free pamphlet “Why, Why, Car Making Research Kids” is available from the Automobile Information Service for Children. It illustrates in simple terms what process a car goes through before it is complete, what a manufacturing plant looks like, how an electric vehicle works, and what initiatives Mitsubishi Motors take for the environment and automotive safety, among others, using photos and pictures.

Prev

Next

1994

Achieved post-war production of a cumulative total of 25 million units of four-wheeled vehicles.

Achieved production of a cumulative total of 25 million engines.

Published an environmental brochure titled Soshite Ashita E (“Toward the Future”).

Introduced automatic transmission “INVECS-II”.

Introduced automatic transmission “INVECS-II”.

Intelligent & Innovation Vehicle Electronic Control System-II (INVECS-II) evolved from the INVECS that was developed in 1992. It had the function of learning the driver’s tendencies and preferences so that it would change gear at the best timing the best timing for the driver. Its computer also had the latest logic circuit for optimum control to select the gear suited to the driving condition with high precision. With its automatic gear shifting, INVECS-II is the transmission that delivers a safe and comfortable ride in driving gear, regardless of the driving condition.

In addition, an epoch-making AT with a "sport mode" function, which allows the driver to enjoy sports driving as if shifting gears manually, was also developed.

In 1995, this technology won the Technological Development Award of the Society of Automotive Engineers of Japan, Inc.

Prev

Next

1995

Manufactured a prototype of hybrid electric vehicle, and conducted tests in collaboration with California Air Resources Board.

Manufactured a prototype of hybrid electric vehicle, and conducted tests in collaboration with California Air Resources Board.

As a hybrid electric vehicle that combined electric cars’ clean emissions and gasoline cars’ maneuverability, Mitsubishi Motors developed the Mitsubishi Hybrid Electric Vehicle (HEV) equipped with an engine for generating and charging electricity that ran on a motor. In April of the year, Mitsubishi Motors became the world’s first automobile manufacturer that entered into an agreement for vehicle tests with the California Air Resources Board (CARB) in the United States and tested three Mitsubishi HEVs to see if they were suited for practical use.